Production related aspects

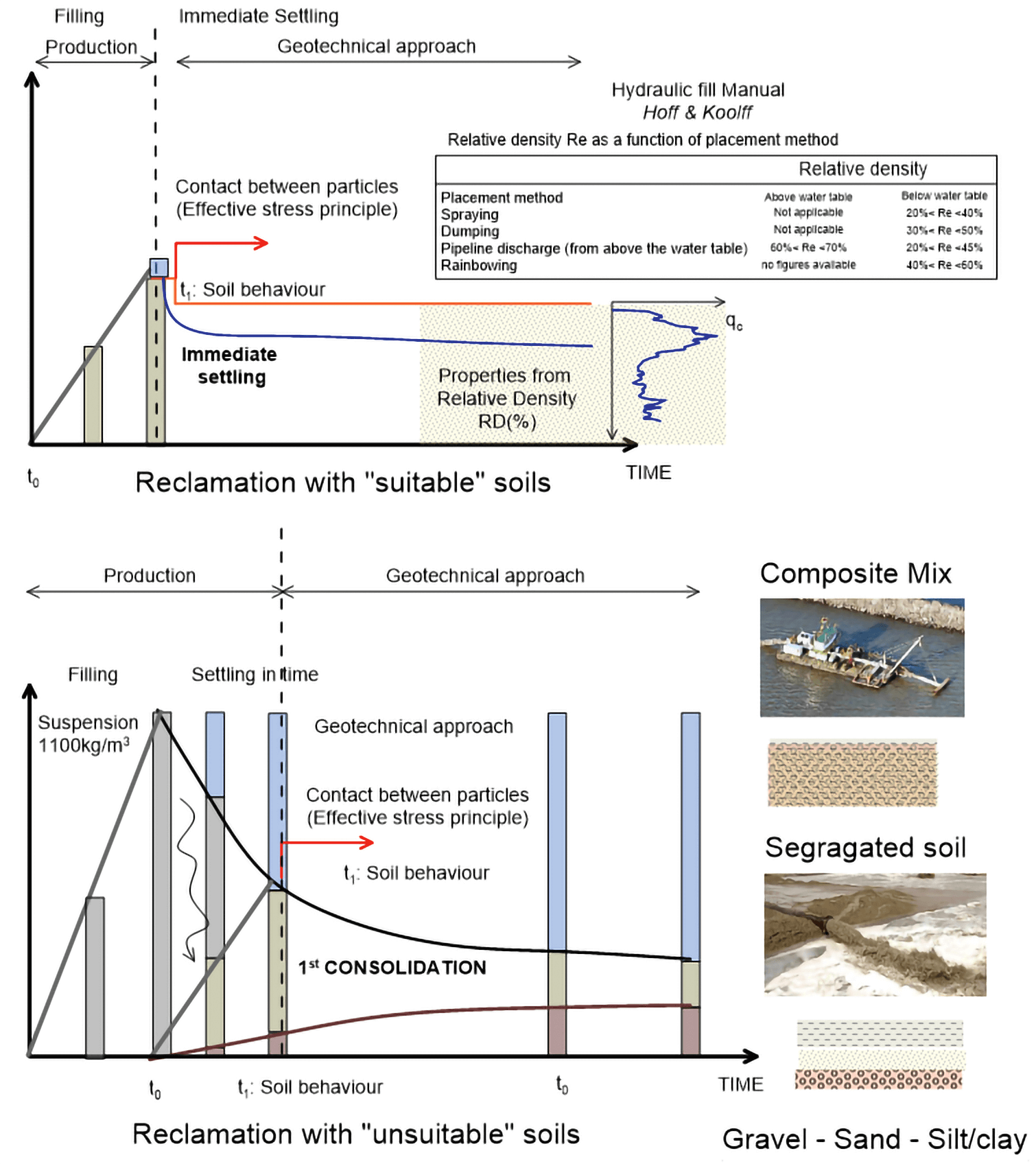

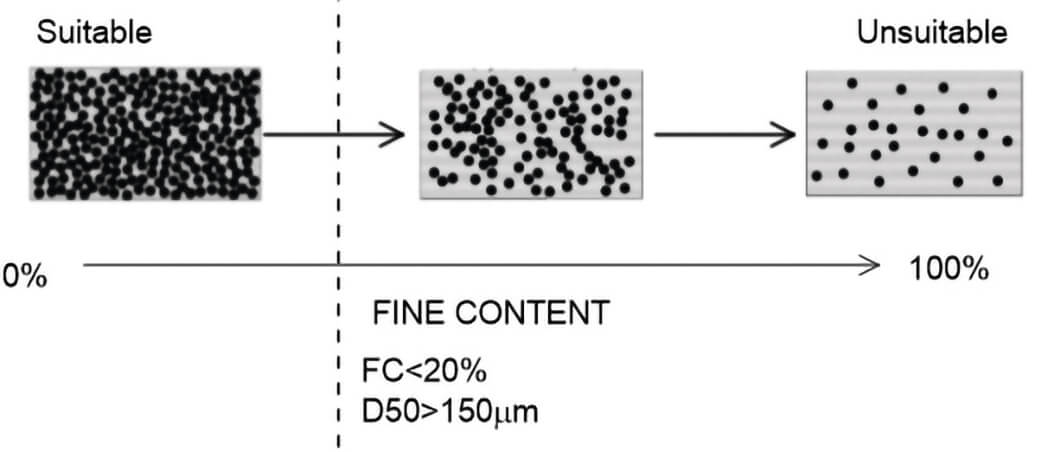

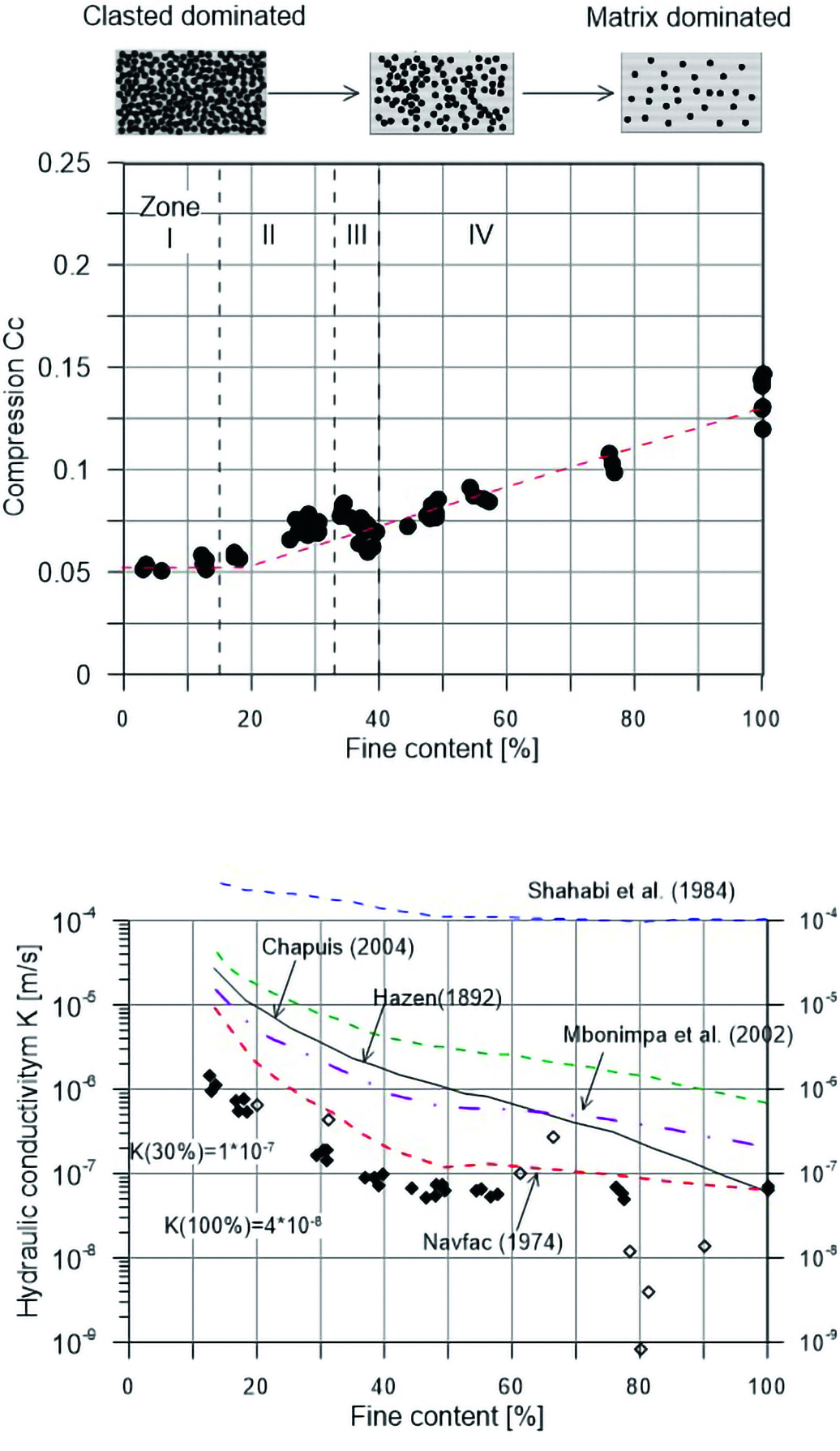

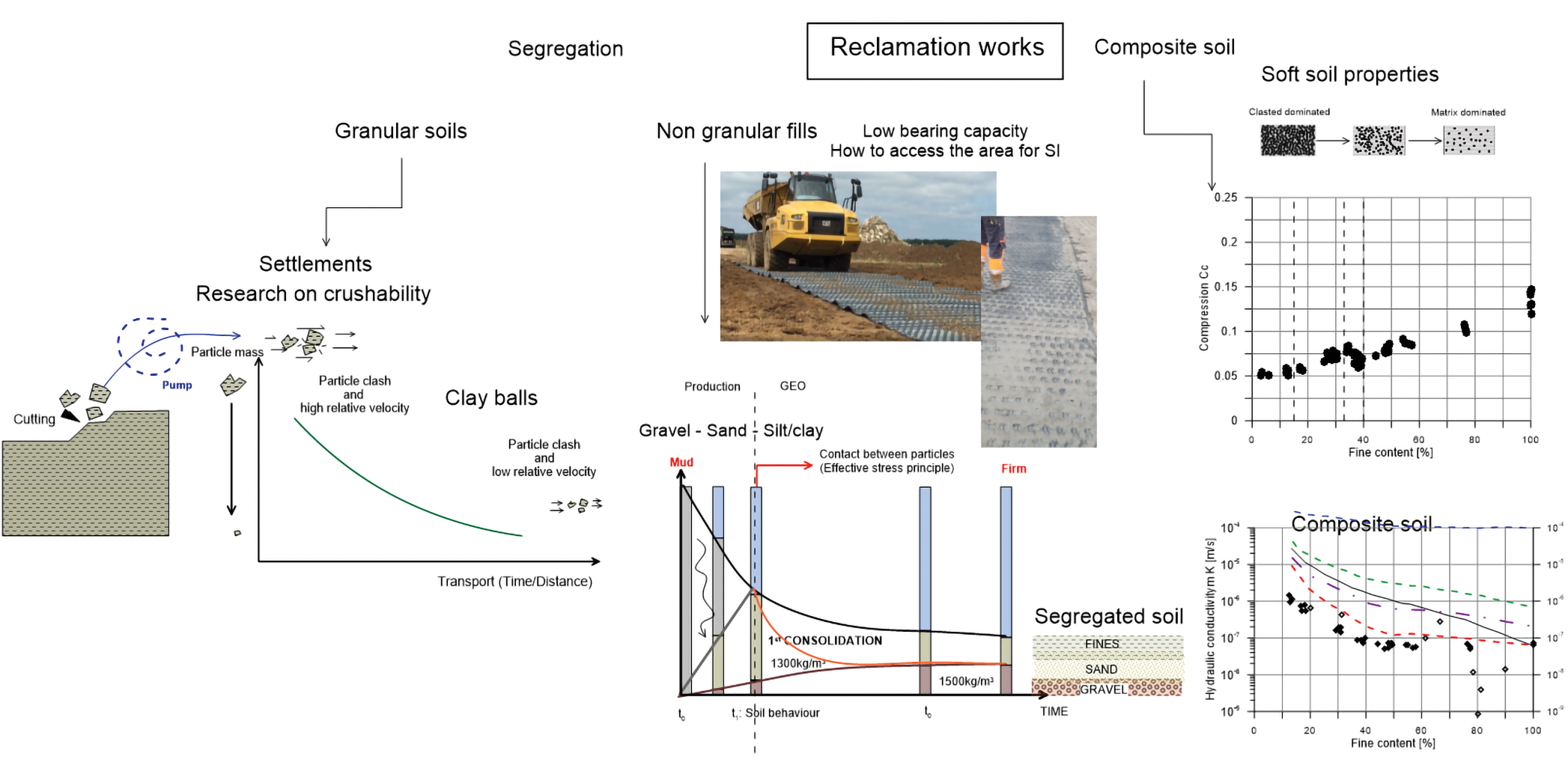

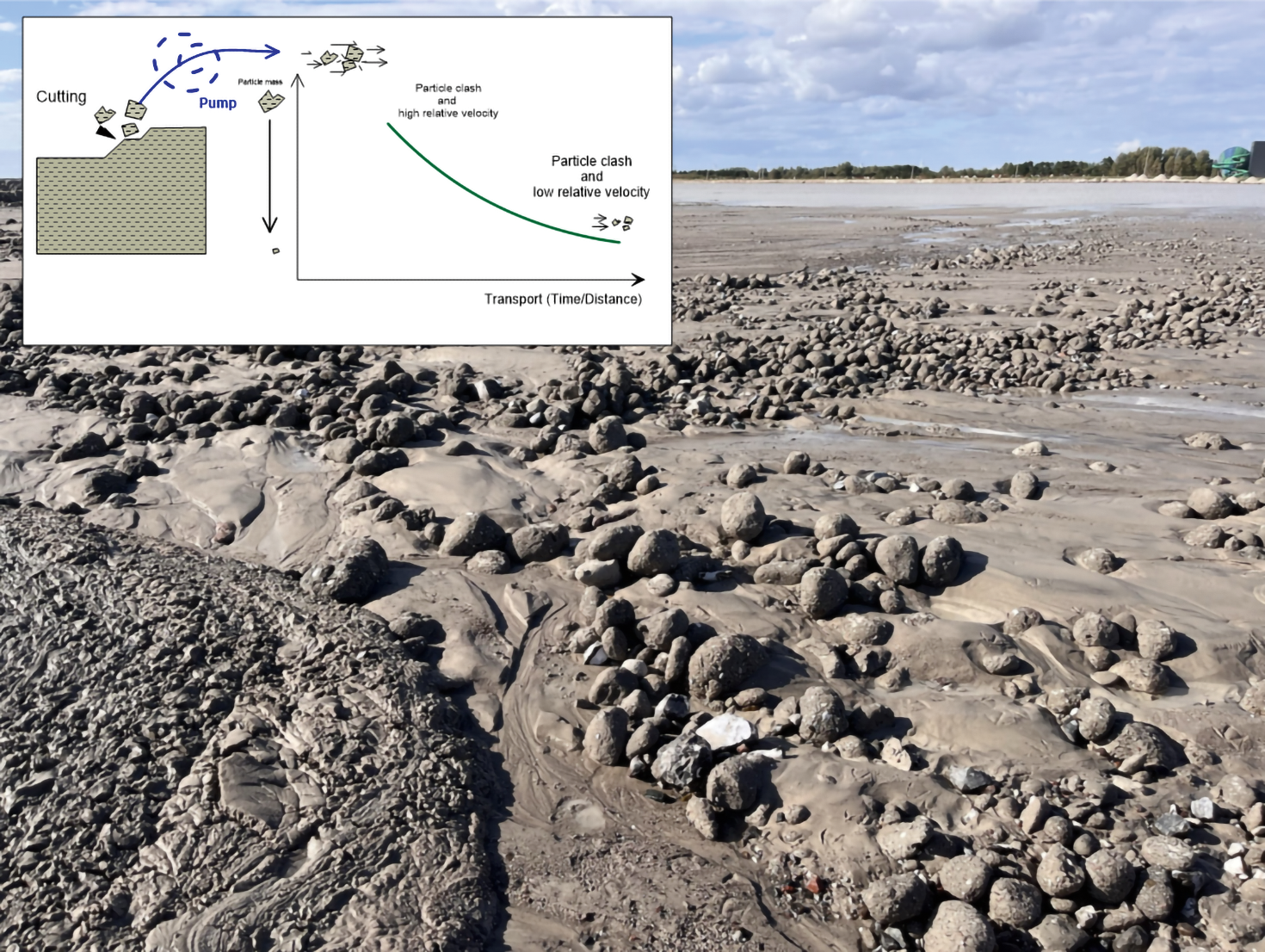

From the production perspective, aspects like

the production rate, production duration and

production costs are to be considered for the

two main dredging work methods: hydraulic

and mechanical dredging. Hydraulic dredging

is often considered to be the fastest and

cheapest dredging method. However, the

counterpart is that the dredged soil is placed

with a significant amount of water resulting in

a fill material characterised by low hydraulic

conductivity and high compressibility.

The consequence of this is that the fill will

require a long consolidation time or a costly

ground improvement method in order to

meet the design requirements. Another

aspect of hydraulic dredging of soft soils is

the high bulking factor.

Mechanical dredging is often considered to

be more expensive and more time consuming

than hydraulic dredging. However, the

advantage of the mechanical method is that it

preserves more the in-situ properties of the

soil. This is because the material is excavated

from the seabed by the bucket and a minimum

of water is added. The resulting fill material is

characterised by a lower water content, a higher

density, a lower compressibility and higher

bearing capacity compared to the material

produced by hydraulic dredging. This will lead to

relatively shorter consolidation times and a

reduction in the amount of ground improvement

required to meet the design requirements.

Bulking factors are also much lower.

The above considerations of the different

dredging methods illustrate that the fastest

and cheapest dredging method may not

necessarily lead to the fastest and cheapest

consolidation phase, especially when using

soils with high fine content. This makes it

evident that a trade-off exists between

total project costs and duration, which is

governed by the chosen dredging work

method. This trade-off element comes

back to the reclamation project when

utilising these materials.

The most efficient dredging work method

is project specific and depends on what

the client and dredging contractor want to

optimise, either the project duration or the

project costs. Despite the project specific

character of the problem, a model is needed

where the production and reclamation

processes can interact and the trade-off

between cost and duration is assessed for

the specific circumstances.

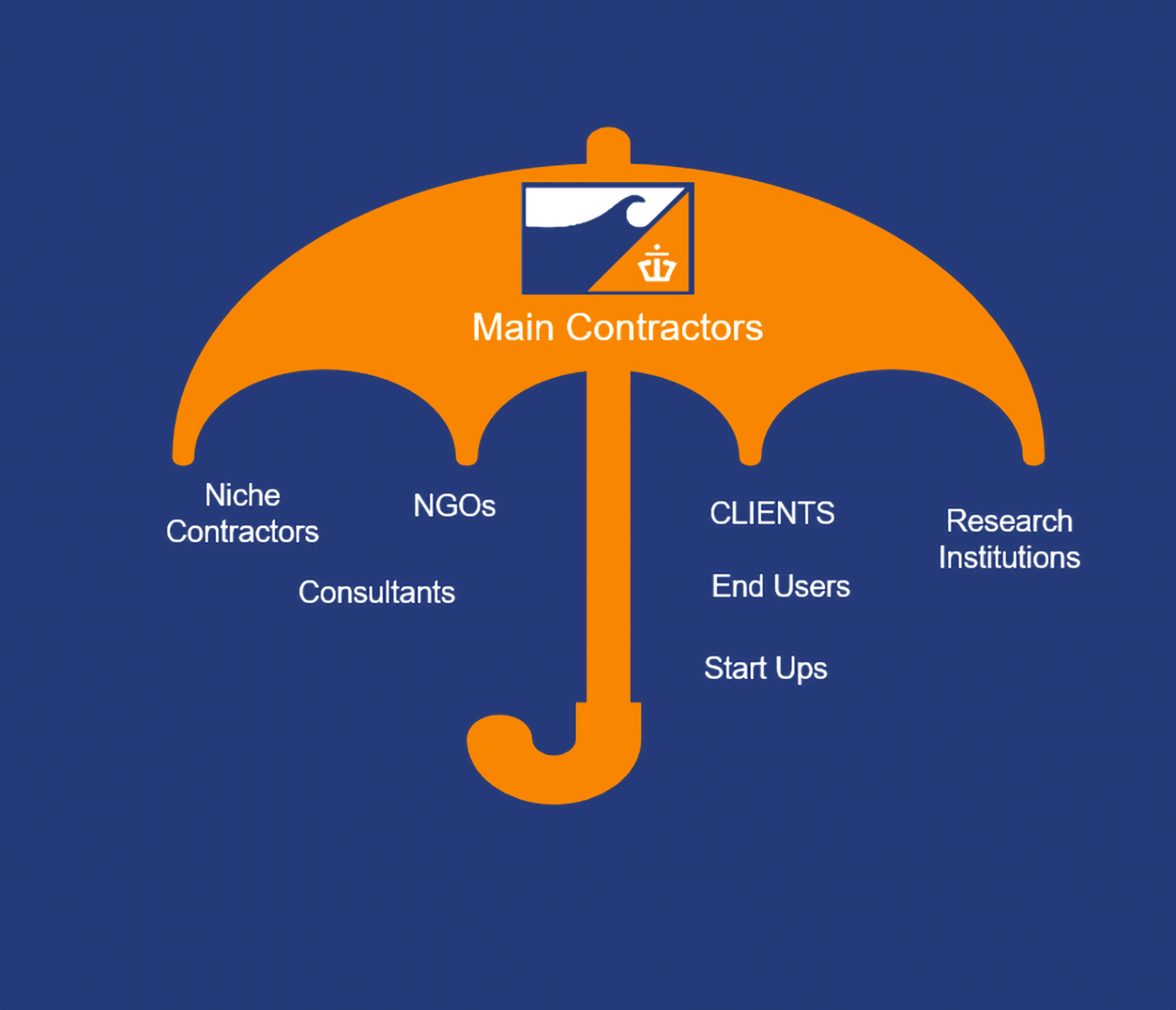

Stakeholders

Stakeholders are recognised to be key players

in the implementation of this mindset change

and for that their involvement is crucial.

Owners and direct users of the reclaimed land

A land reclamation reaches airports, port

developments or housing areas. The direct

users of a land reclamation are affected by the

fact that a land reclamation could enhance

their business opportunities. Changes in the

project duration will have an impact on the

faster or slower return on their investments.

Direct users should then be involved in the

discussion and their feedback considered for

the performance requirements in terms of

need for maintenance, costs associated with

an increase or decrease in the operability and

the overall quality of the end product. The core

value regarding this integrated approach is

to have a reliable product that does not fail.

Environmentalists and NGOs

The creation of new land by reclamation will

potentially affect the current ecosystem,

which in principle is not in favour of the

environmentalists. The involvement of

environmentalists and NGO organisations

will favour the realisation of the project and

produce a positive effect on the local

communities. Introducing solutions like the

Building with Nature programme will favour

the acceptance of the project by the local

communities leading to a better balance

between the needs of the project area.

Increasing the efficiency of project execution

would result in a shorter relative duration of

the construction phase and, as an effect,

reduce its negative impact on the ecosystem

in terms of noise pollution and disturbance by

operations. Choosing the most CO2-neutral

dredging work method makes a more healthy

and sustainable solution possible. Otherwise,

the option for the cheapest work method

would allow for some extra budget to build

compensation elements on the reclamation,

such as new habitats for several species and

more value to society (for example, beaches).

The core responsibility of environmentalists

and NGOs is to be involved in the discussion to

express their opinion on the optimum solution.

The core values regarding this integrated

framework are trust and transparency

regarding the environmental impacts of the

execution method of land reclamation and

the land reclamation itself.

Contractors

Contractors can increase their project's

efficiency in terms of total project costs and

duration. This could enable the contractor

to increase its competitive position in tenders

or increase the profit margin of a project.

The contractor will strengthen its market

position in the long term. The core responsibility

of the contractor is to increase the efficiency

of their operations, deliver reliable assets to

clients and leave a positive impact on the

environment and society. The core values of

this civil engineering (CE) system are quality,

safety, innovation, and financial responsibility.

Government

The government can benefit from the

optimisation of the duration and costs for

the completion of a project. Increased

efficiency in project execution could lead

to cheaper reclamation options, which make

the reclamation of land more attractive for

various public problems, such as housing,

airport expansions and port developments.

It is the responsibility of the government to

complete a project finding the best solution

in terms of sustainability, cost and time.

The core values regarding this CE system

are safety, sustainability, transparency and

public benefit.

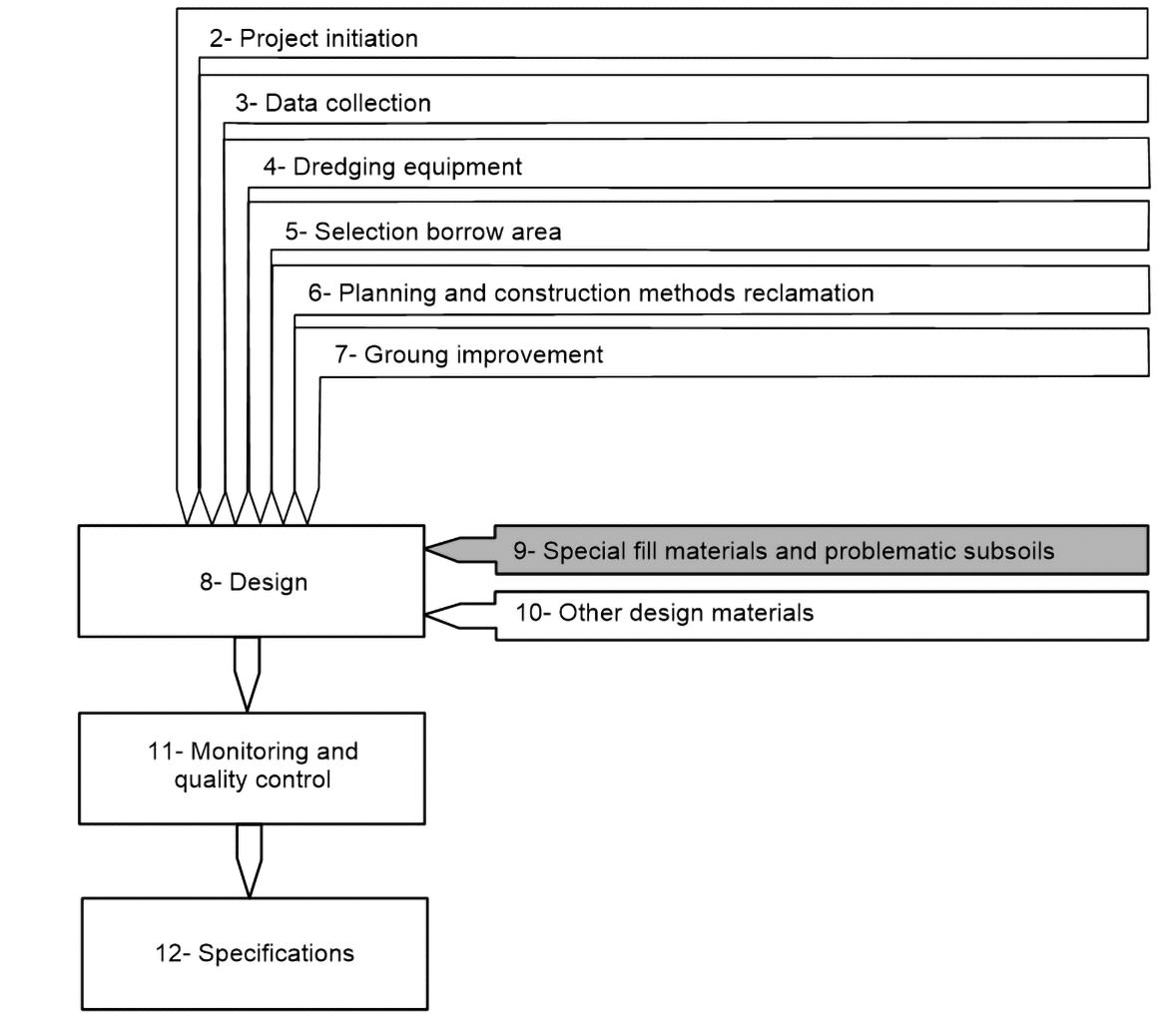

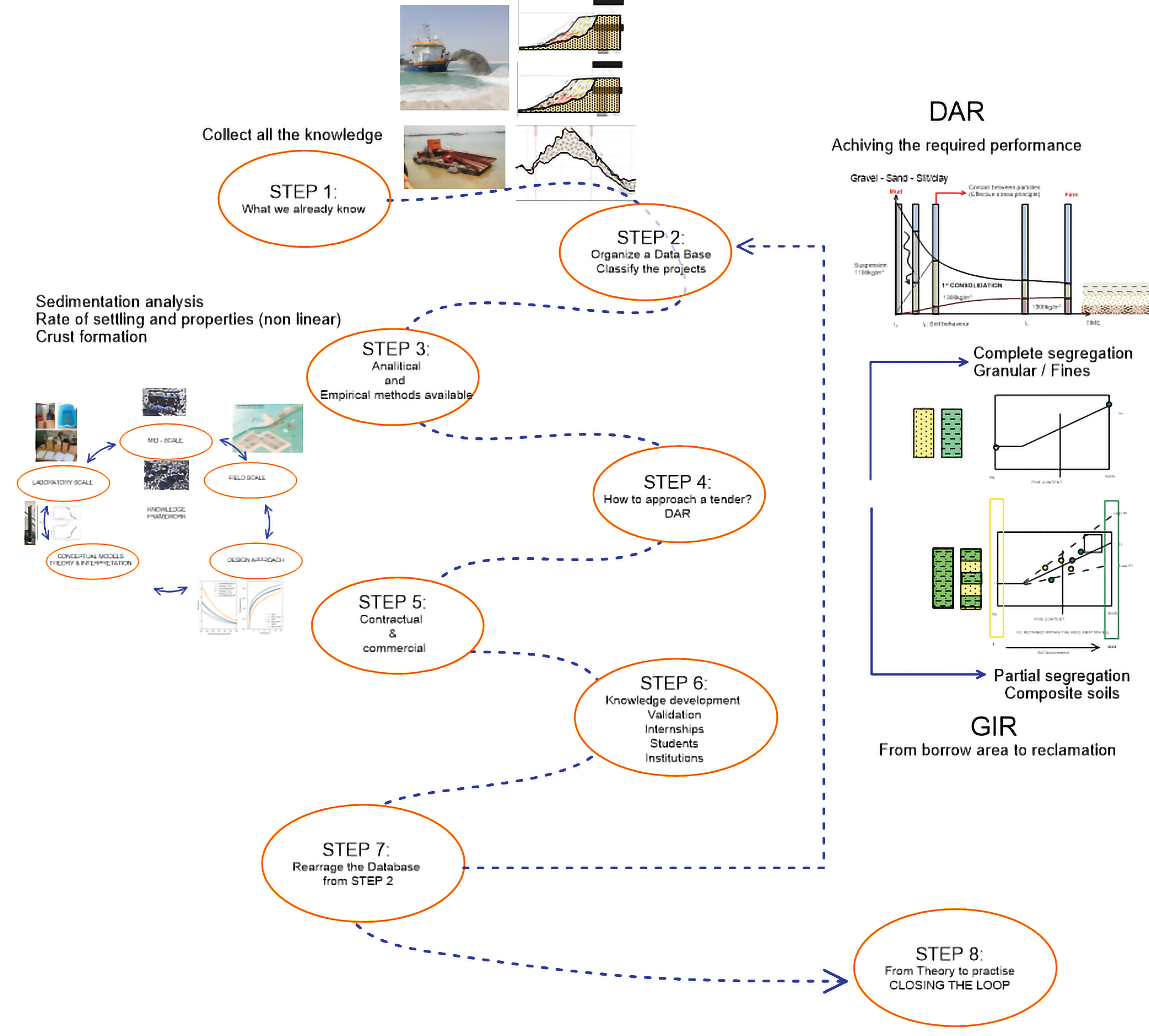

Proposed roadmap

In the process of developing an adequate

framework for the exchange of knowledge

between disciplines and to provide access to

this knowledge to all relevant actors involved

in these kinds of projects, the following steps

are proposed to compose a possible road map

(Figure 13).