JAN DE NUL’S AWARD WINNING CUTTER HEAD STAIRCASE

Design evolution

The development of the cutter head

staircase has been a continuous journey

to improve safety and efficiency during

repairs. Over the years, various designs

have aimed to address concerns like

difficult installation, height-related hazards

and operational inefficiencies. However,

earlier versions often fell short, with larger

structures and limited flexibility that

complicated the repair process.

Initial designs lacked ergonomic

considerations, leaving workers in awkward,

unsafe positions and increasing the risk

of injury. Later models introduced more

complex scaffolding systems, which

improved access but required significant

setup time and specialised training, making

them impractical for quick repairs. A more

recent innovation involved a donut shaped

working platform, which improved safety but

had its own limitations. As a result, many

welders reverted to older, less safe methods

due to the inefficiencies of these designs.

Despite these challenges, the aim has

remained constant: to create a practical,

adaptable and safe solution for cutter head

repairs. The latest version builds on the

lessons learnt from previous designs,

offering a modular and ergonomic system

that addresses earlier shortcomings,

providing improved safety, ease of use

and operational efficiency.

Improvements

Modular flexibility

The current cutter head staircase is designed with improved modularity, making it easier to disassemble, move and reassemble. This increased flexibility allows for adaptation to various cutter head sizes and work environments, ensuring a better fit for our international operations.

Ergonomic improvements

A focus of the design is reducing worker fatigue and minimising the risk of musculoskeletal injuries. The current ergonomic features allow welders to work in safer, more comfortable postures, significantly reducing the strain that was common in earlier versions.

Improved operational control

The new design improves stability and access to cutter heads. Non-slip steps and secure railings provide better support, allowing workers to perform tasks with greater precision and reduced risk of falls. The elimination of rigging and lifting requirements further contributes to a safer, more controlled working environment.

Benefits in practice

This design brings significant practical improvements that offer valuable benefits in the field.

- Reduction in incidents: The improved stability and user-friendly design have resulted in a decrease in accidents such as slips and falls as well as near misses. Workers can now operate with greater confidence and security, particularly when welding on a cutter head.

- Employee comfort: The ergonomic improvements allow workers to maintain more comfortable postures, reducing the risk of strain or injury. This not only has a positive impact on the well-being of workers but also leads to higher productivity, as tasks can be completed more efficiently without frequent breaks due to discomfort.

- Operational efficiency: By simplifying assembly and eliminating the need for rigging, the new design reduces downtime and operational costs. The staircase’s adaptability to different cutter head sizes streamlines workflows, making the repair process faster and more cost effective.

- Positive worker feedback: Workers have responded positively to the new staircase, praising its ease of use and comfort. This feedback has translated into improved morale, job satisfaction and a more motivated team, further contributing to a safer work environment.

Frank Verhoeven, President, IADC presents the Safety Award to Mieke Fordeyn, Director International Department, Jan De Nul.

SUPPLY CHAIN WINNER: CSPECT’S ALTUM TELESCOPIC POLE SYSTEM

The ALTUM telescopic pole system has been developed to easily perform inspections and operations at height or depth. This patented system is an in-house development by Cspect and provides a safe and cost-effective solution for conducting general and detailed inspections. With this system, the need for scaffolding, ladders, aerial work platforms, or cranes for inspections or thickness measurements at height or depth is eliminated. For example, hopper walls can be inspected without entering them, depth markers onboard can be checked without deploying rescue boats, the inside of tanks can be inspected remotely... the list goes on.

Cspect is an engineering company based in the Port of Ostend,

Belgium, using and selling “Remote Inspection Techniques” to inspect

assets. We eliminate the use of divers for inspections below water and

the use of staging, cranes, ladders, rope access or cherry pickers for

close-up inspections and thickness measurements at height or depth.

To perform these remote inspections, we use Remotely Operated

Vehicles (ROV) and our revolutionary ALTUM telescopic pole system.

The system has the additional advantage of not being bound to any

rule or regulation such is often the case with drones for example.

Consisting of different modules that can be attached on top of

an ultra-light, 20-metre telescopic pole, the ALTUM system is

built to be used by those working on the shop floor. It therefore

eliminates the need for extra drone pilots, robotic engineers and

other high-end equipment. The system is quick and easy to setup

and can be deployed for 12 hours without battery stress. It can be

carried as standard hand luggage/baggage on a plane. Our inspectors

fly all over the world or the system can be used by the crew themselves.

Currently there are two modules available: The ALTUM with

the VISUAL module to perform close-up inspections and the

ALTUM with the UTM module to perform Ultrasonic Thickness

Measurements (with grinding and hammering facility).

The ALTUM system has been thoroughly tested on the dredgers

Sanderus and Tristão Da Cunha, both operated by Jan De Nul.

Inspections targeted critical areas, including visual inspections of

hopper holds, overflow systems, dredging marks, loading boxes, hopper

nozzles, ballast tanks, cranes, suction pipes and gantries. In addition to

the visual inspections, thickness measurements were also taken on

the dredge pipes, hopper walls, loading boxes, overflows, stems, cross

beams, etc. Importantly, these inspections were conducted without

the use of cranes, scaffolding or entry into the hopper, eliminating work

at height and fully adhering to standard safety rules and regulations.

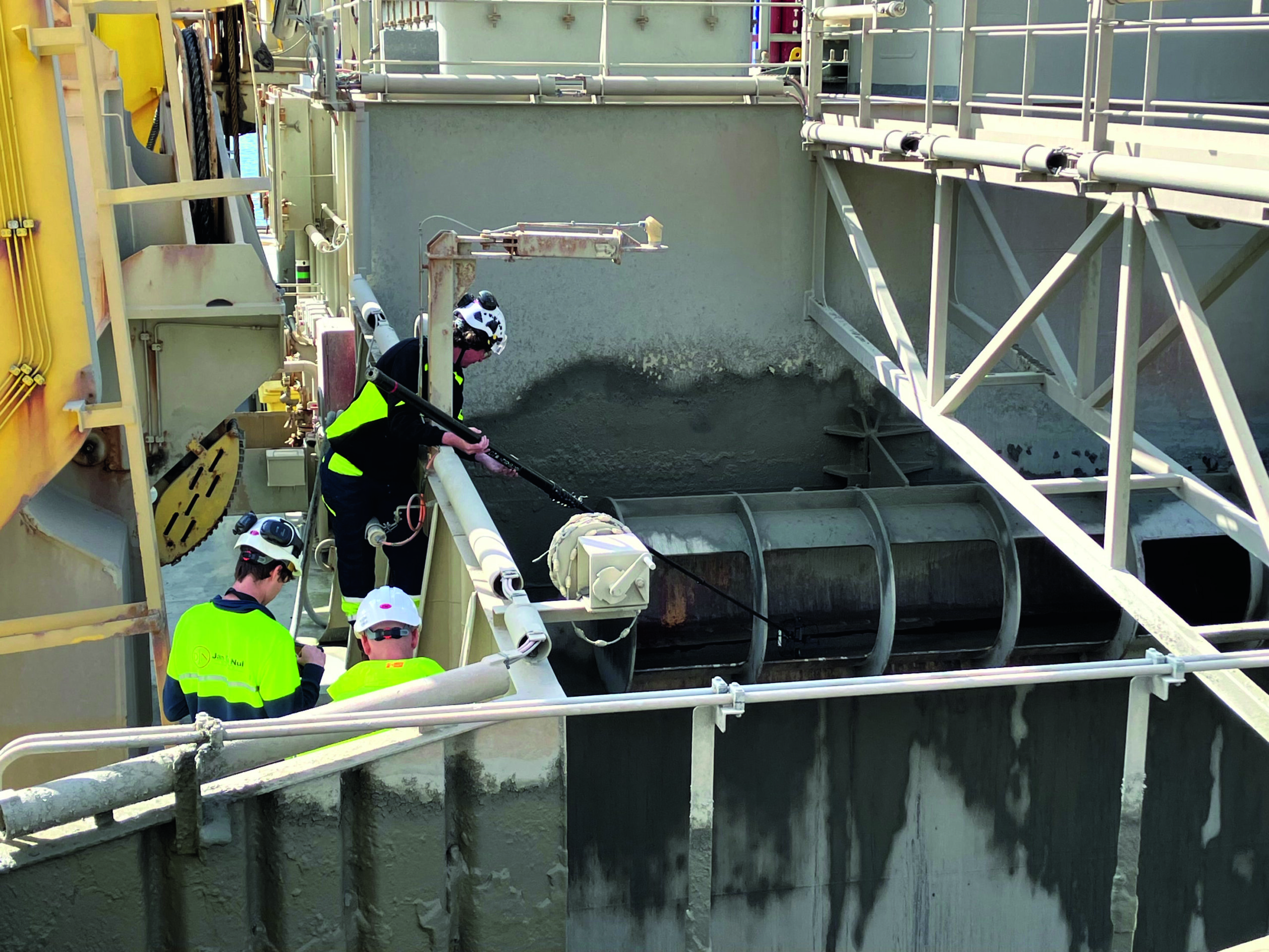

Taking thickness measurements of hopper wall

Making visual inspection of trunnion gantry and loading boxes (opposite)