Since the 19th century, dredging and reclamation projects have taken place around the world (Borel, 1867). Its processes have undeniable impacts on the footprint of the newly created areas and the ecosystems adjacent to those areas. The potentially negative impacts to the environment can be minimised when proper mitigation measures are adopted prior and during the execution of works and when proper environmental management is present throughout the course of the project. Mitigation measures refer to all measures aiming at minimising or eliminating factors that can potentially negative influence physical, biotic and socioeconomic environments within and surrounding the works.

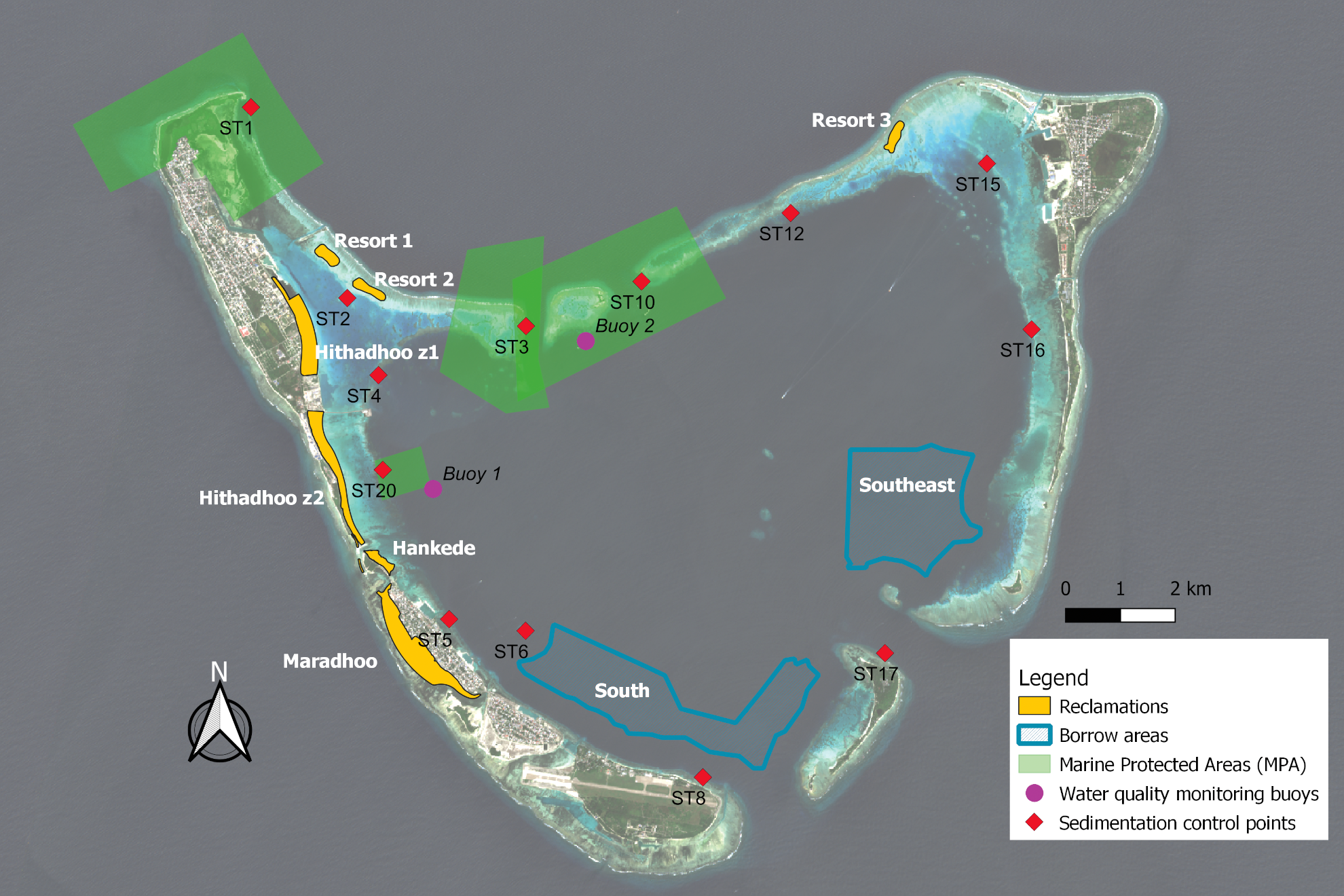

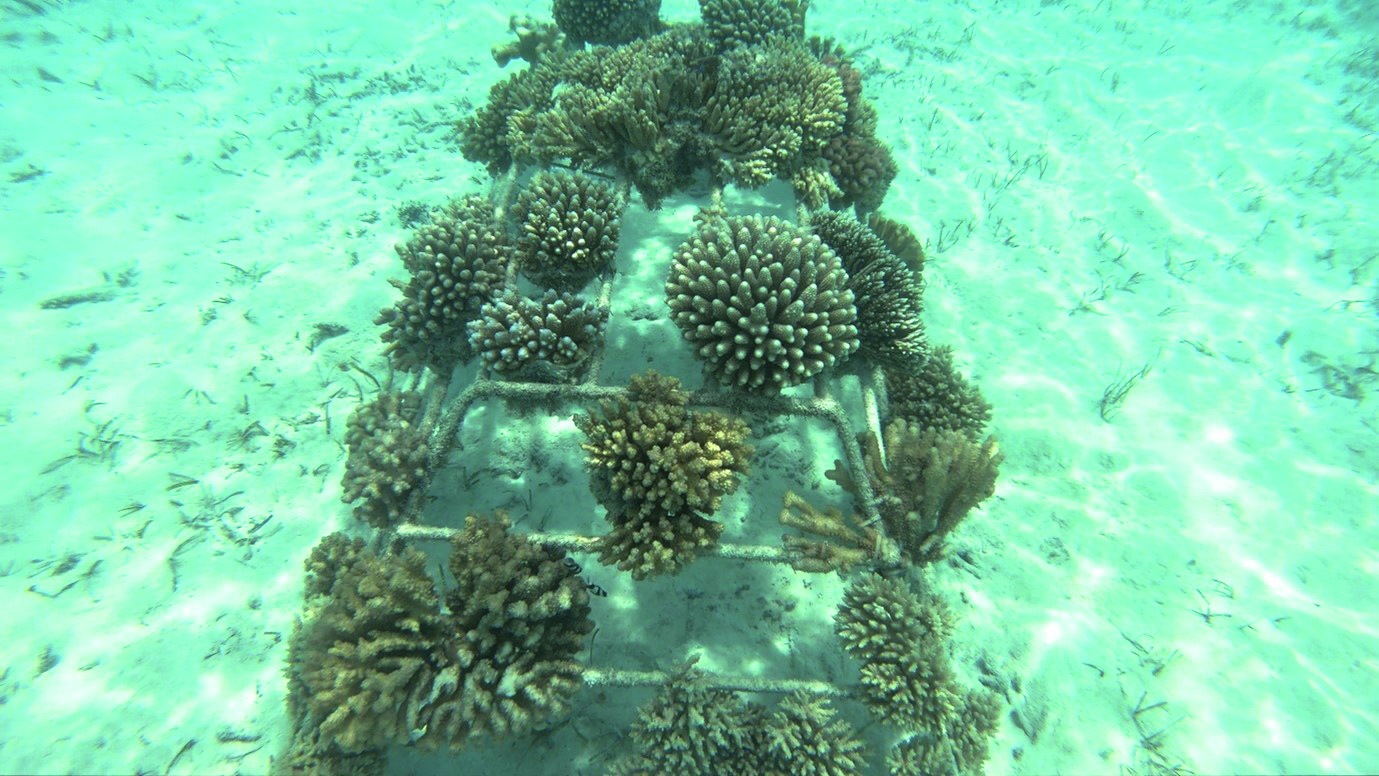

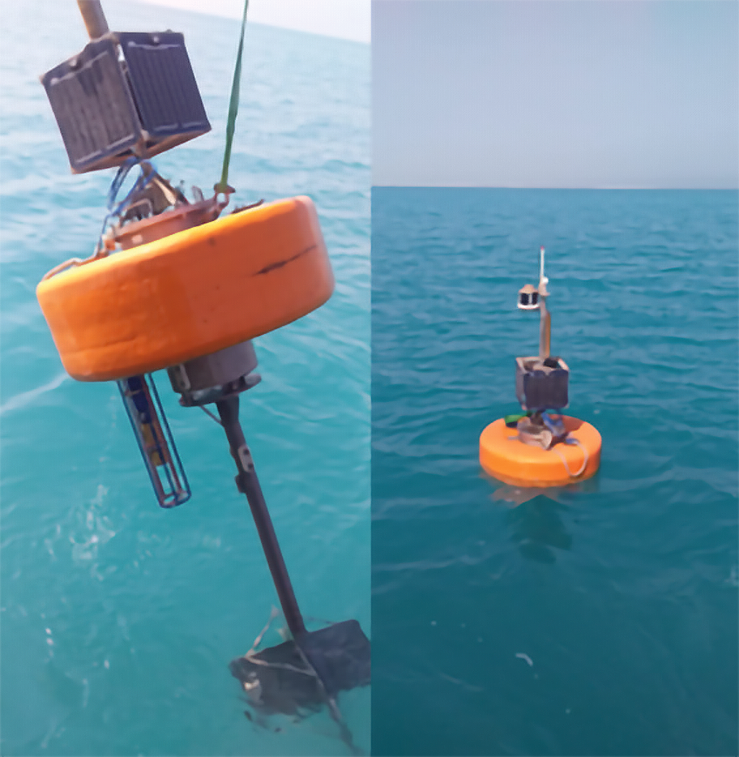

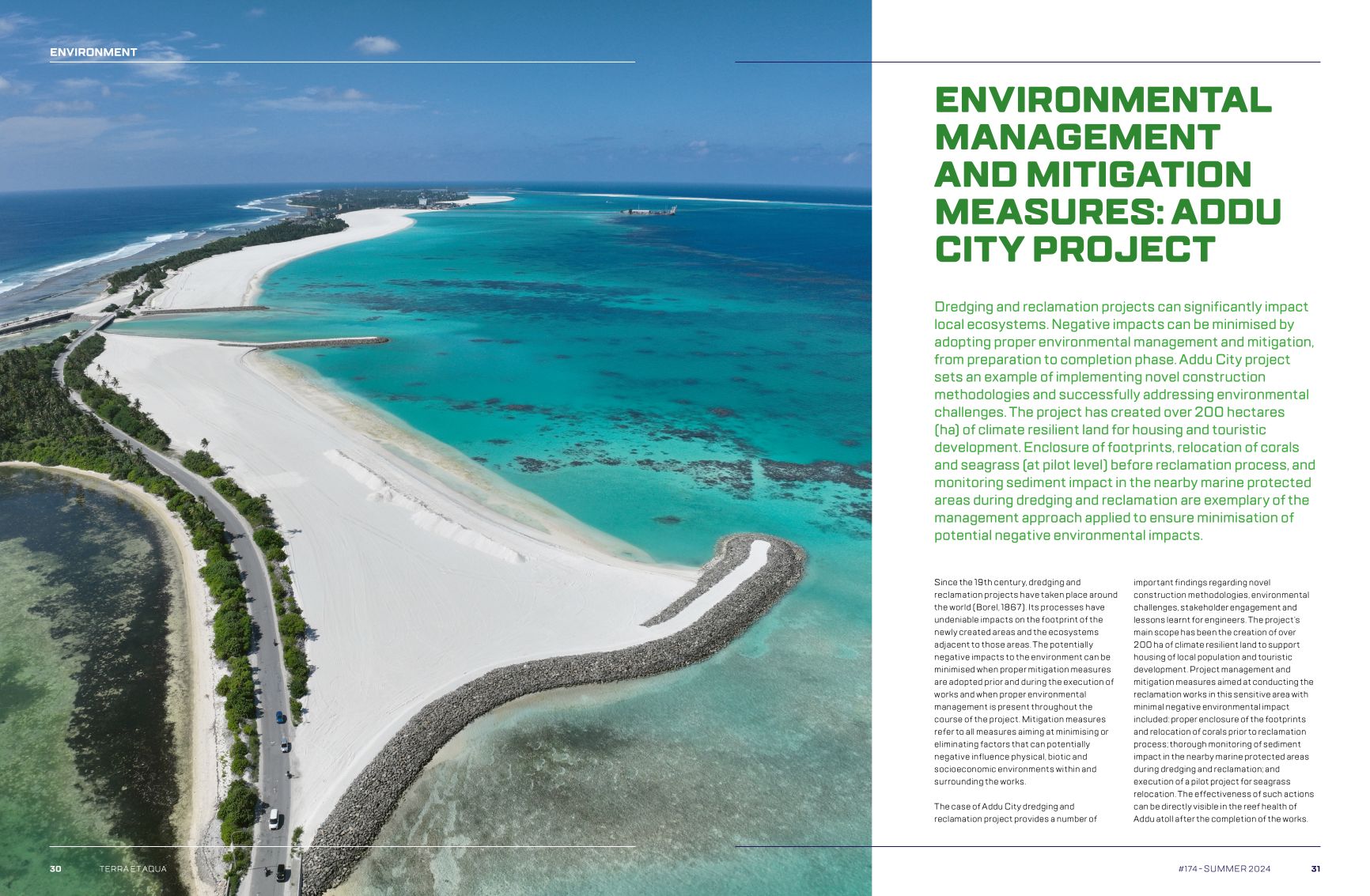

The case of Addu City dredging and reclamation project provides a number of important findings regarding novel construction methodologies, environmental challenges, stakeholder engagement and lessons learnt for engineers. The project’s main scope has been the creation of over 200 ha of climate resilient land to support housing of local population and touristic development. Project management and mitigation measures aimed at conducting the reclamation works in this sensitive area with minimal negative environmental impact included: proper enclosure of the footprints and relocation of corals prior to reclamation process; thorough monitoring of sediment impact in the nearby marine protected areas during dredging and reclamation; and execution of a pilot project for seagrass relocation. The effectiveness of such actions can be directly visible in the reef health of Addu atoll after the completion of the works.

In this article, the sequence of events along with the results of environmental actions and initiatives will be shared. The importance of a detailed and high-quality Environmental Social Impact Assessment (ESIA) will be highlighted to identify environmental challenges as early as possible in preparation. The Addu City dredging and reclamation project deployed one of the highest set of standards for management practices in a very effective manner. This approach can be adopted for projects of similar magnitude and sensitivity within and outside the region.

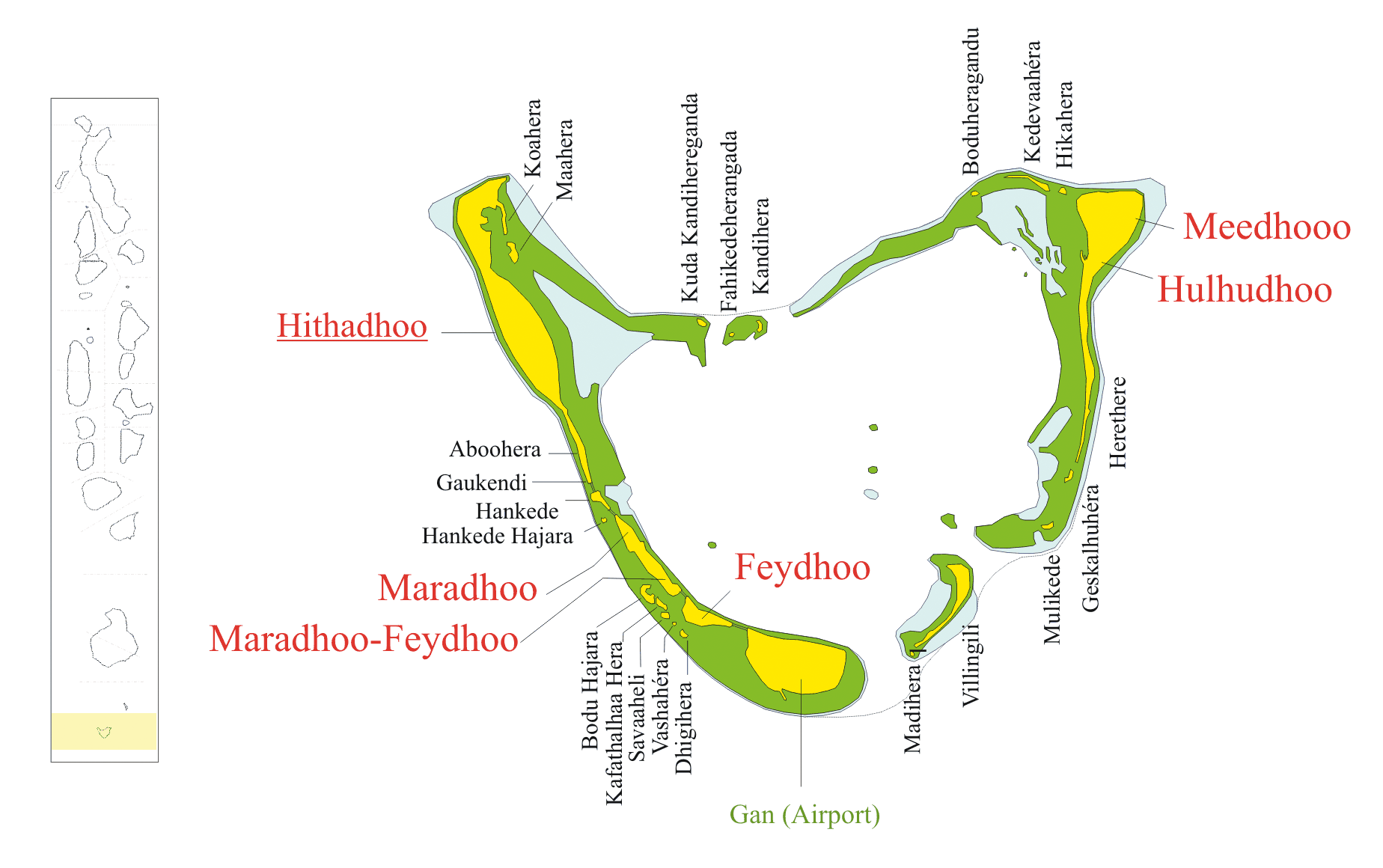

The project location

The Addu City dredging and reclamation project (referred hereafter as the project) took place in the Addu or Seenu Atoll (Figure 1). This southernmost atoll of the Republic of Maldives. Addu City consists of the inhabited islands of Gan, Feydhoo, Maradhoo, Hithadhoo and Hulhumeedhoo (Hulhudhoo-Meedhoo).