What is Trisoplast?

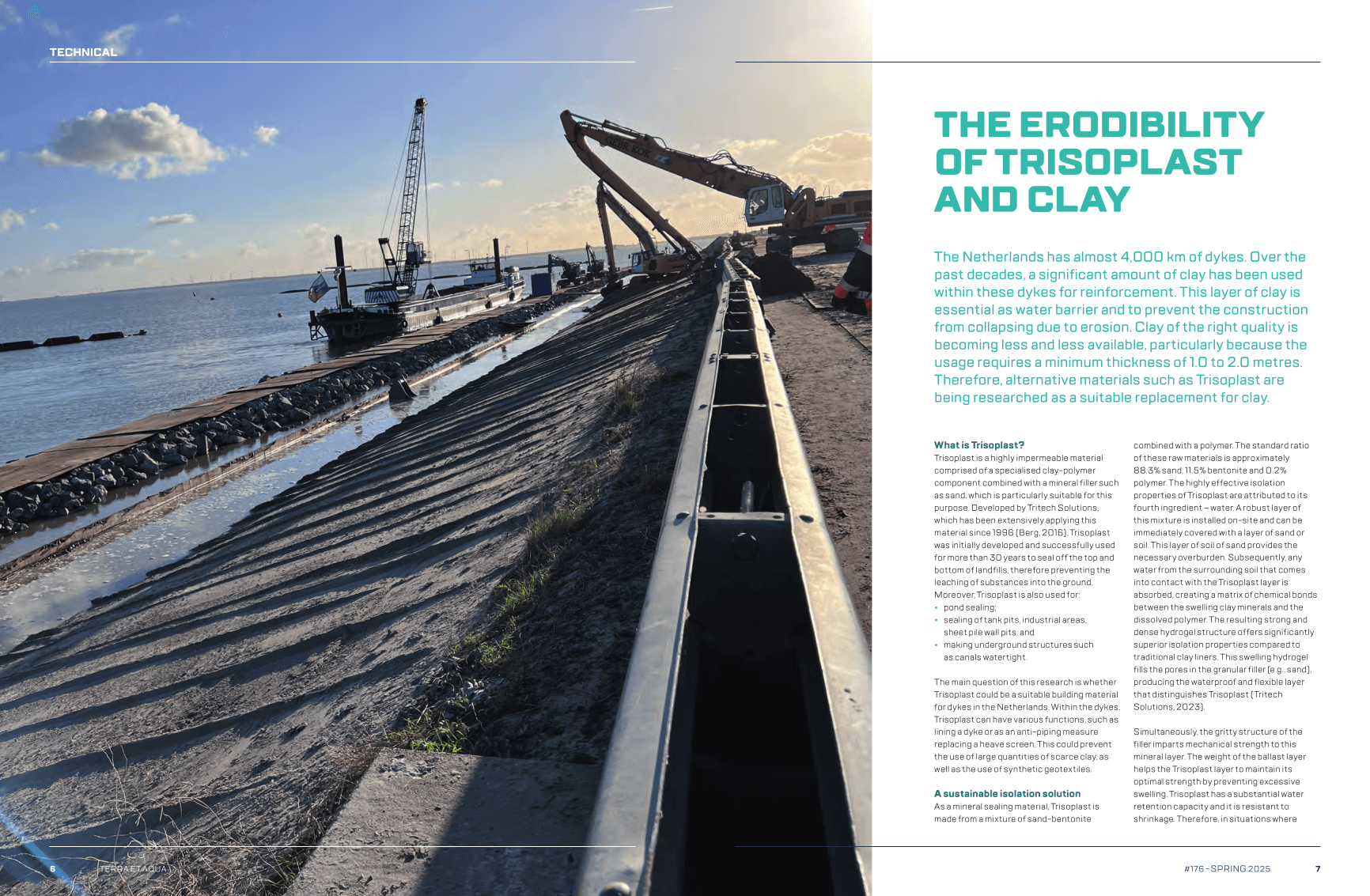

Trisoplast is a highly impermeable material comprised of a specialised clay-polymer component combined with a mineral filler such as sand, which is particularly suitable for this purpose. Developed by Tritech Solutions, which has been extensively applying this material since 1996 (Berg, 2016), Trisoplast was initially developed and successfully used for more than 30 years to seal off the top and bottom of landfills, therefore preventing the leaching of substances into the ground. Moreover, Trisoplast is also used for:

- pond sealing;

- sealing of tank pits, industrial areas, sheet pile wall pits; and

- making underground structures such as canals watertight.

The main question of this research is whether Trisoplast could be a suitable building material for dykes in the Netherlands. Within the dykes, Trisoplast can have various functions, such as lining a dyke or as an anti-piping measure replacing a heave screen. This could prevent the use of large quantities of scarce clay, as well as the use of synthetic geotextiles.

A sustainable isolation solution

As a mineral sealing material, Trisoplast is made from a mixture of sand-bentonite combined with a polymer. The standard ratio of these raw materials is approximately 88.3% sand, 11.5% bentonite and 0.2% polymer. The highly effective isolation properties of Trisoplast are attributed to its fourth ingredient – water. A robust layer of this mixture is installed on-site and can be immediately covered with a layer of sand or soil. This layer of soil of sand provides the necessary overburden. Subsequently, any water from the surrounding soil that comes into contact with the Trisoplast layer is absorbed, creating a matrix of chemical bonds between the swelling clay minerals and the dissolved polymer. The resulting strong and dense hydrogel structure offers significantly superior isolation properties compared to traditional clay liners. This swelling hydrogel fills the pores in the granular filler (e.g., sand), producing the waterproof and flexible layer that distinguishes Trisoplast (Tritech Solutions, 2023).

Simultaneously, the gritty structure of the filler imparts mechanical strength to this mineral layer. The weight of the ballast layer helps the Trisoplast layer to maintain its optimal strength by preventing excessive swelling. Trisoplast has a substantial water retention capacity and it is resistant to shrinkage. Therefore, in situations where traditional clay liners tend to dry out and crack, Trisoplast will maintain its elasticity. Together, these properties result in a durable, safe and simple liner that is quick to install. Even when it has to be fitted around numerous connections (Tritech Solutions, 2020).

Flow flumes

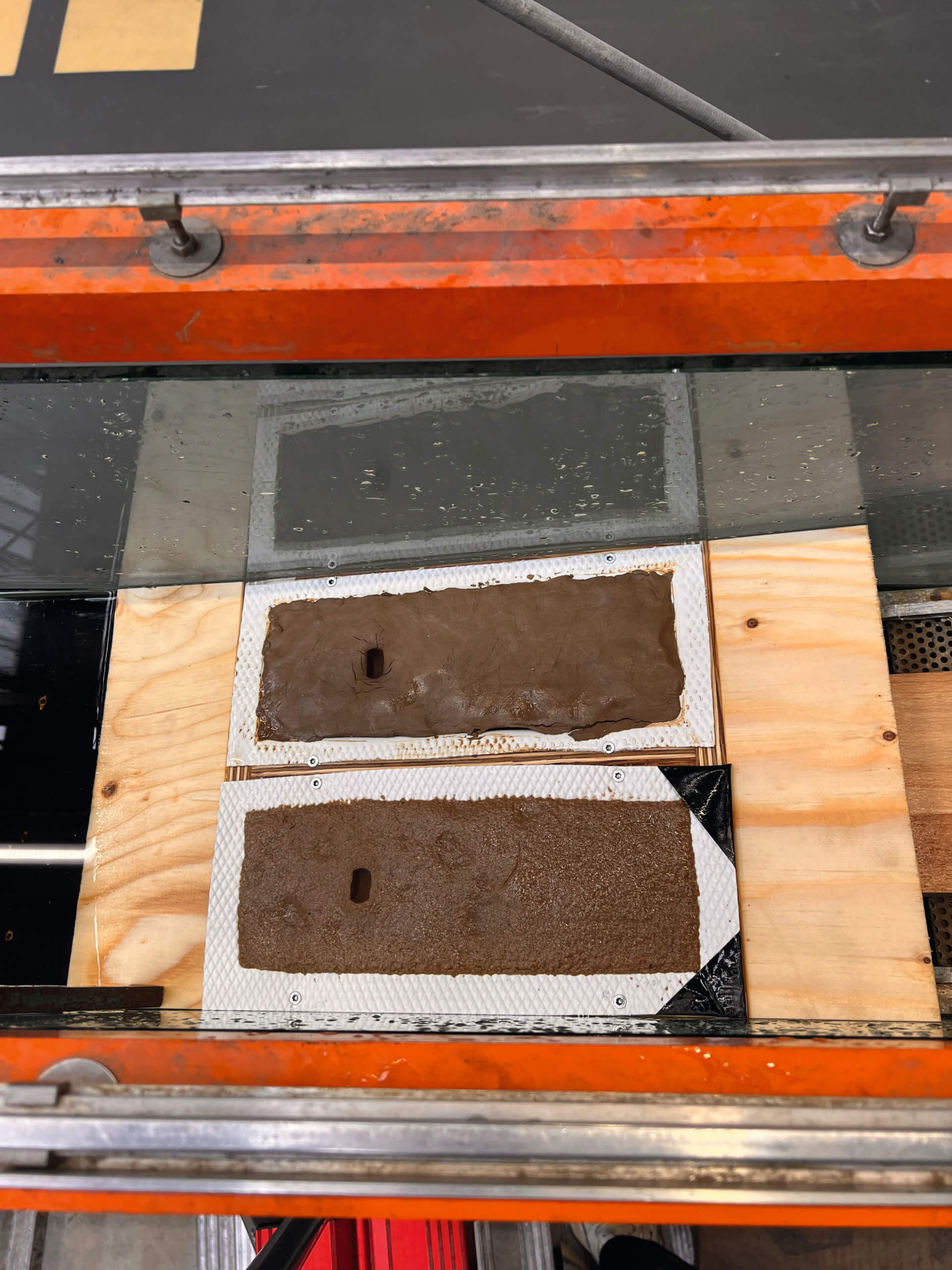

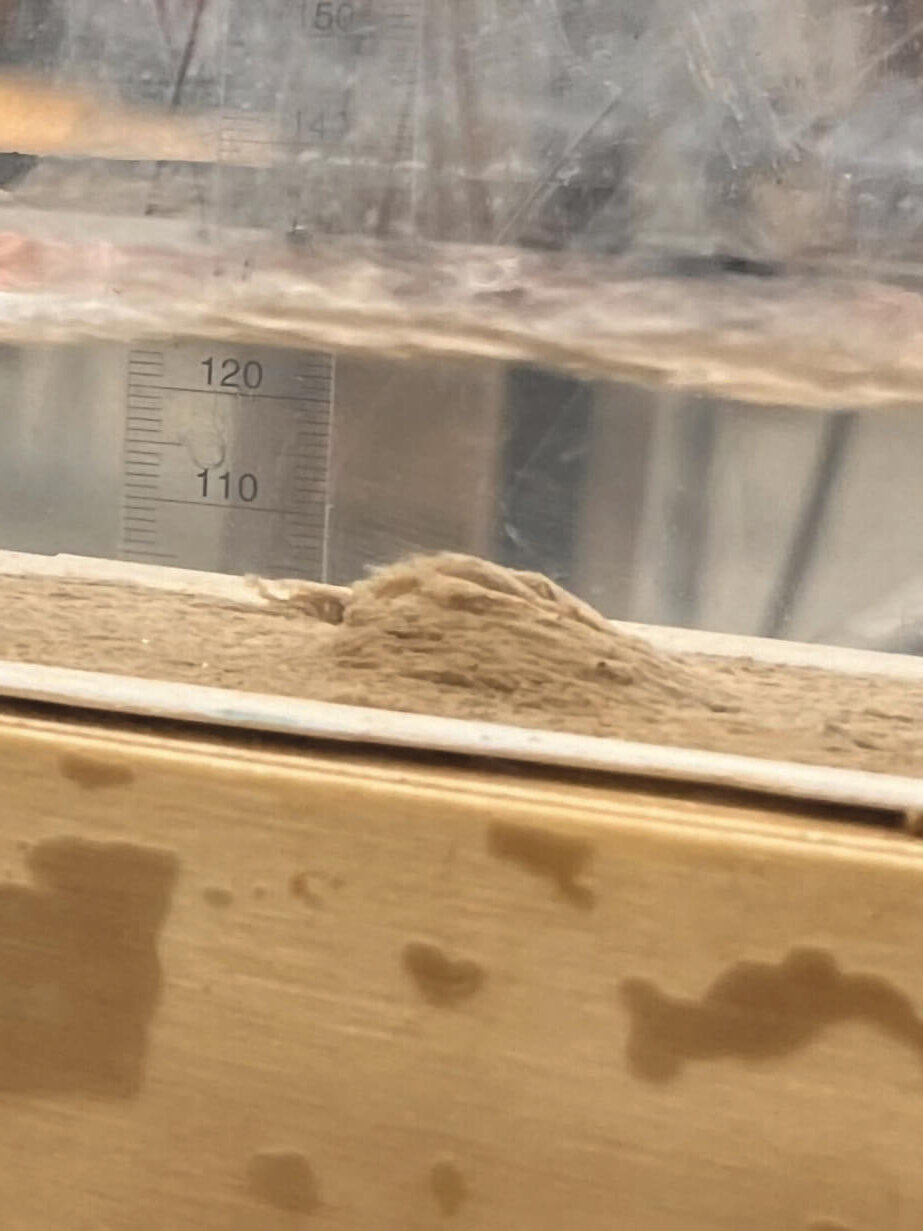

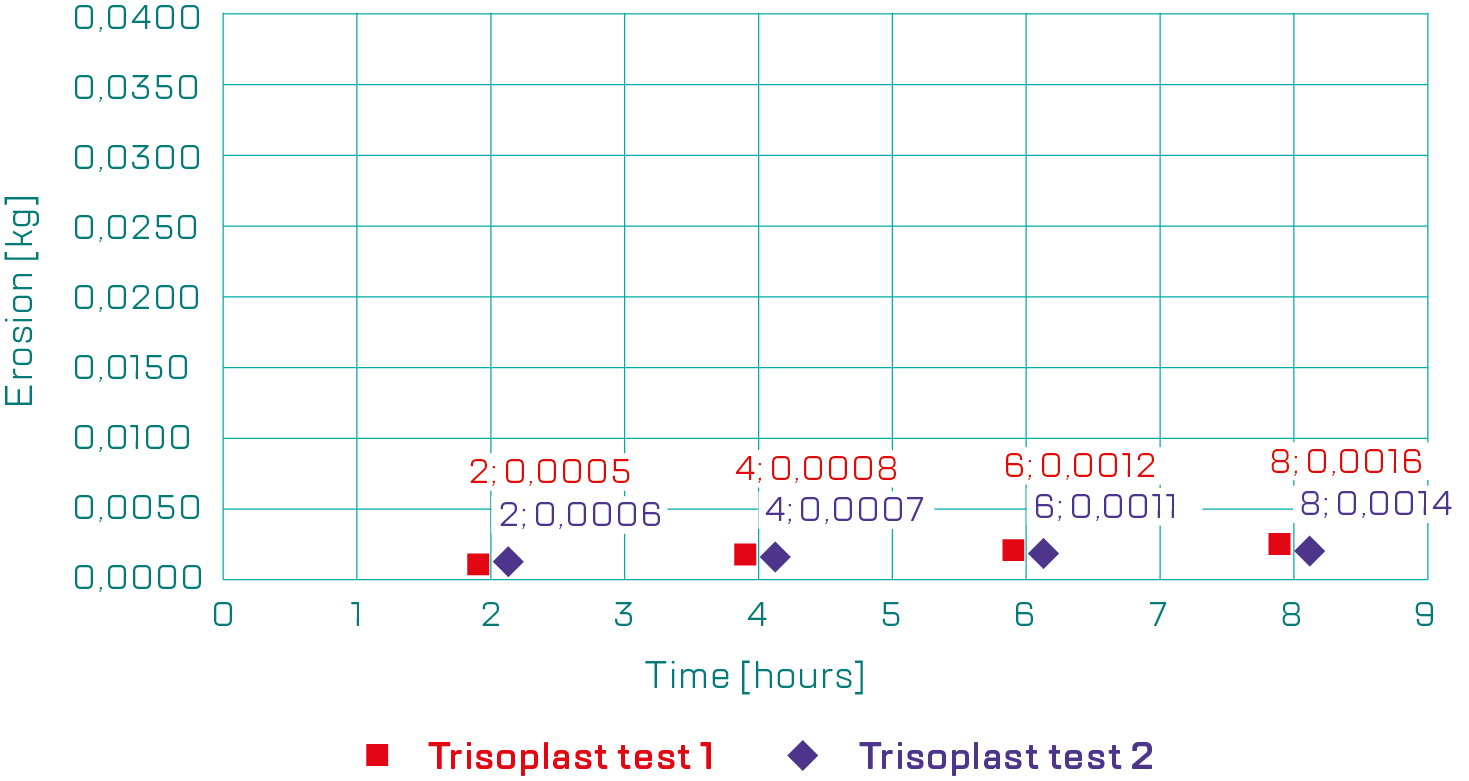

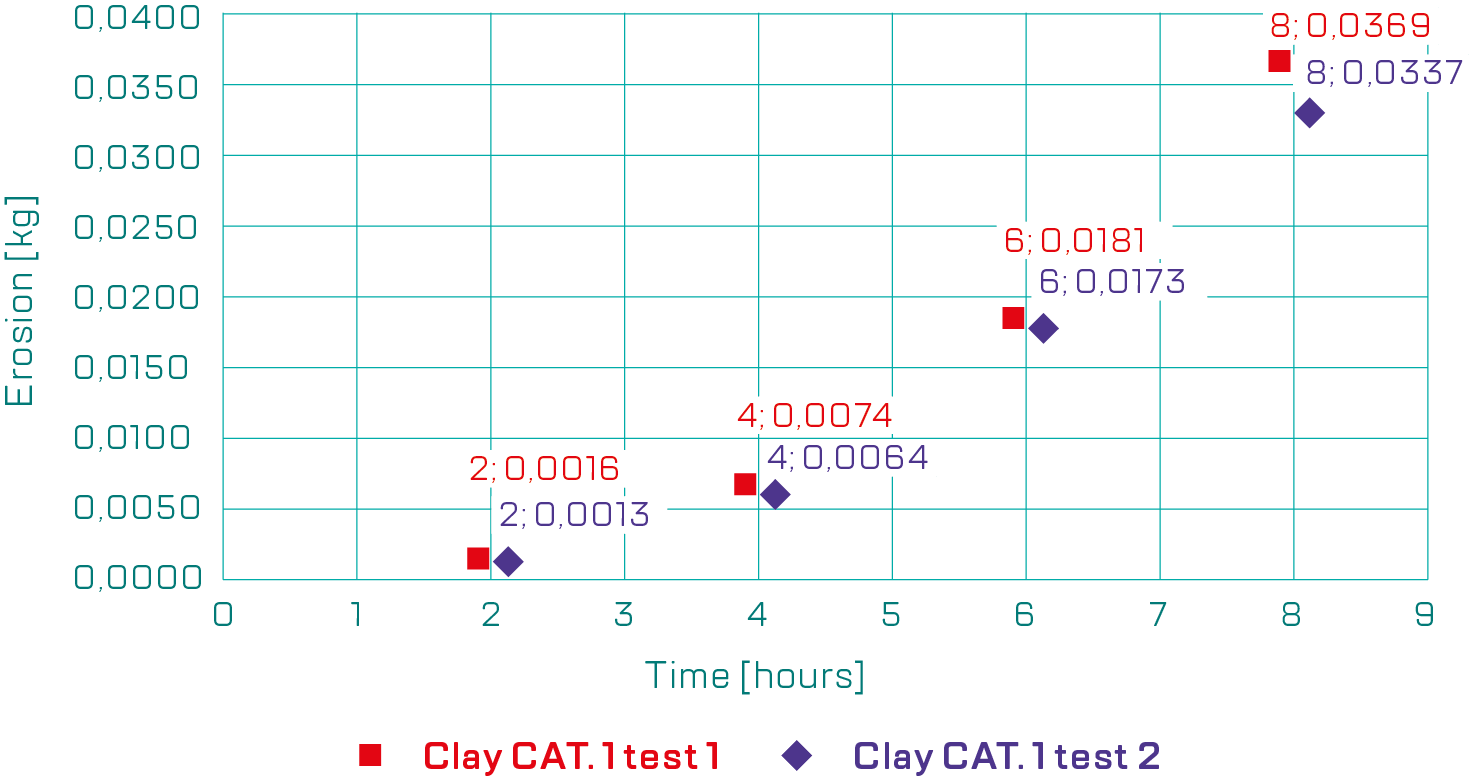

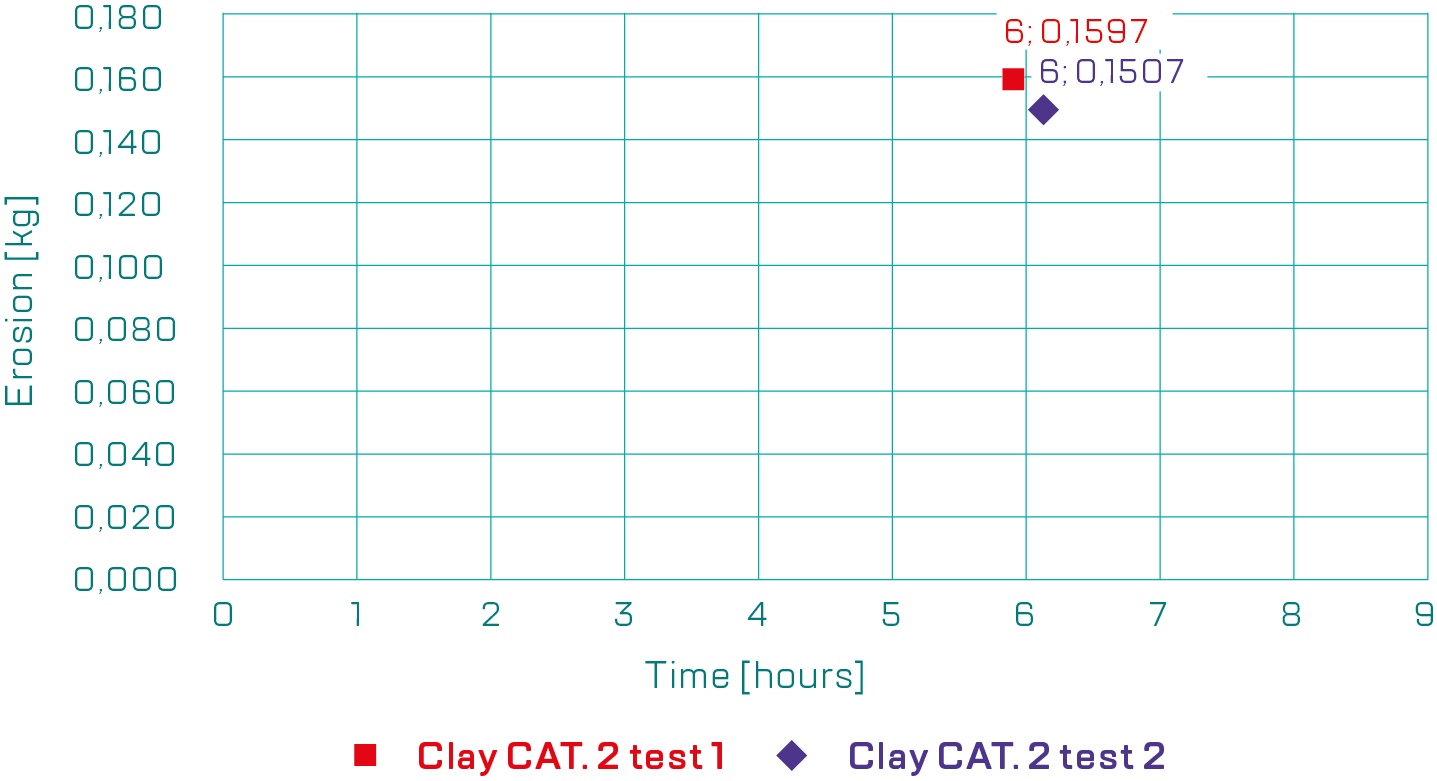

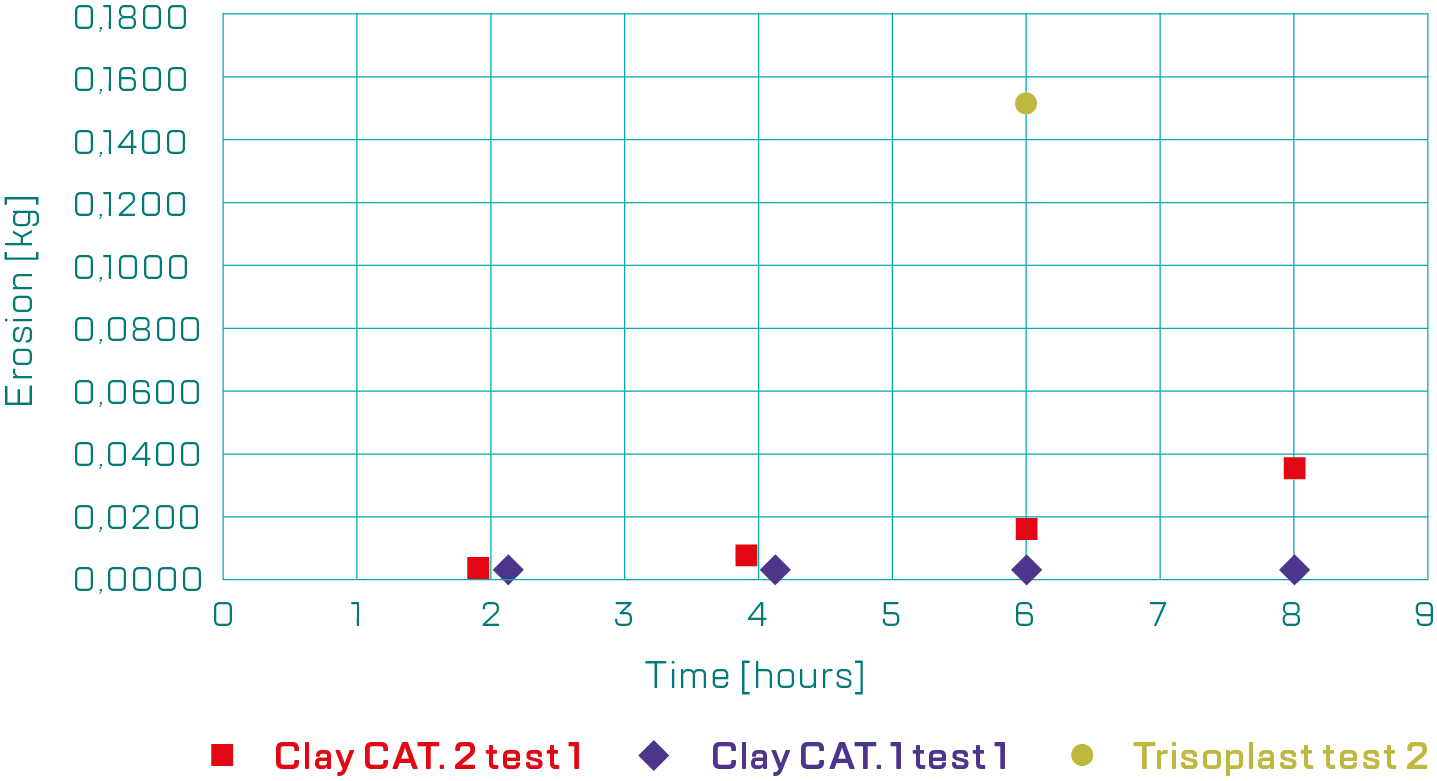

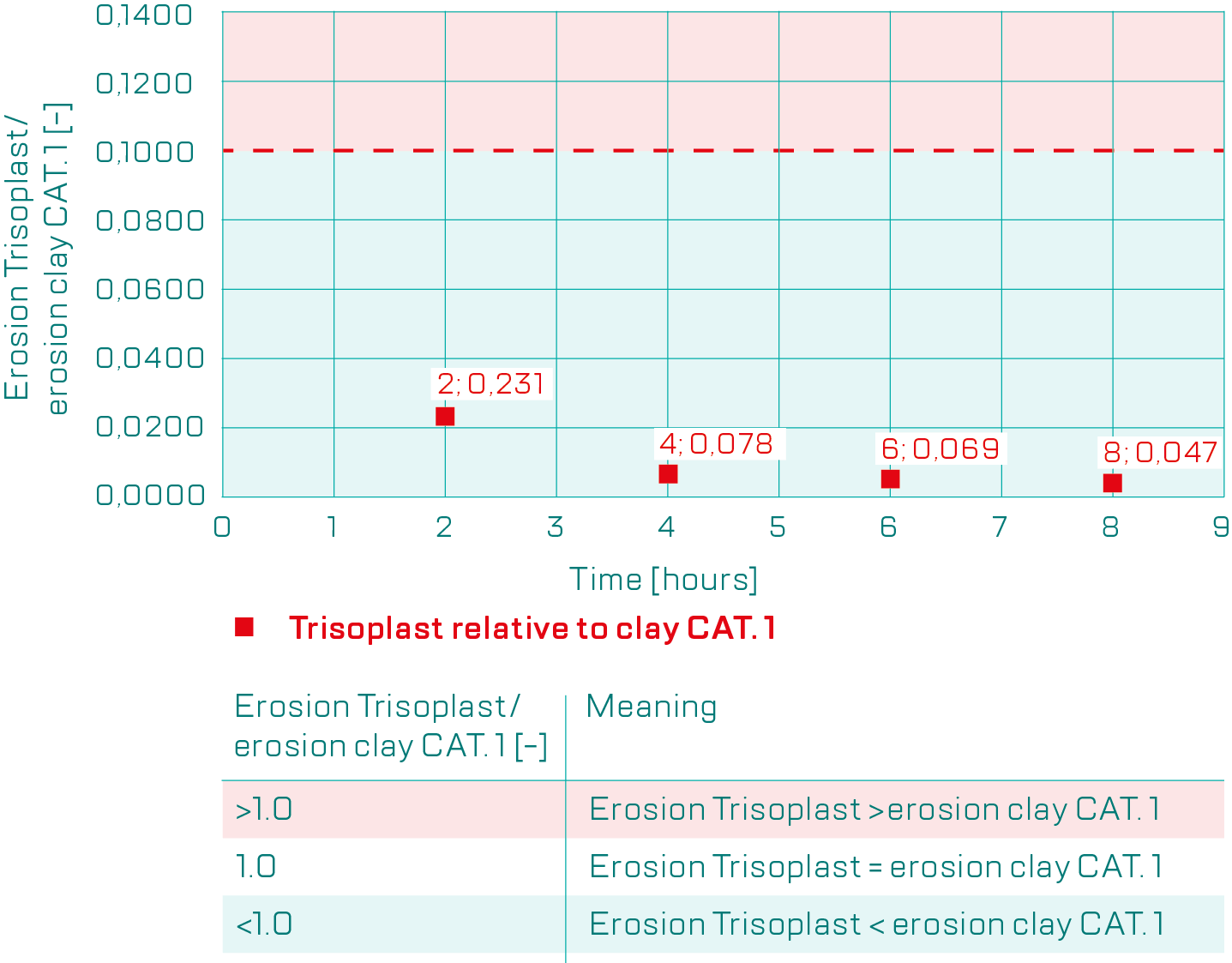

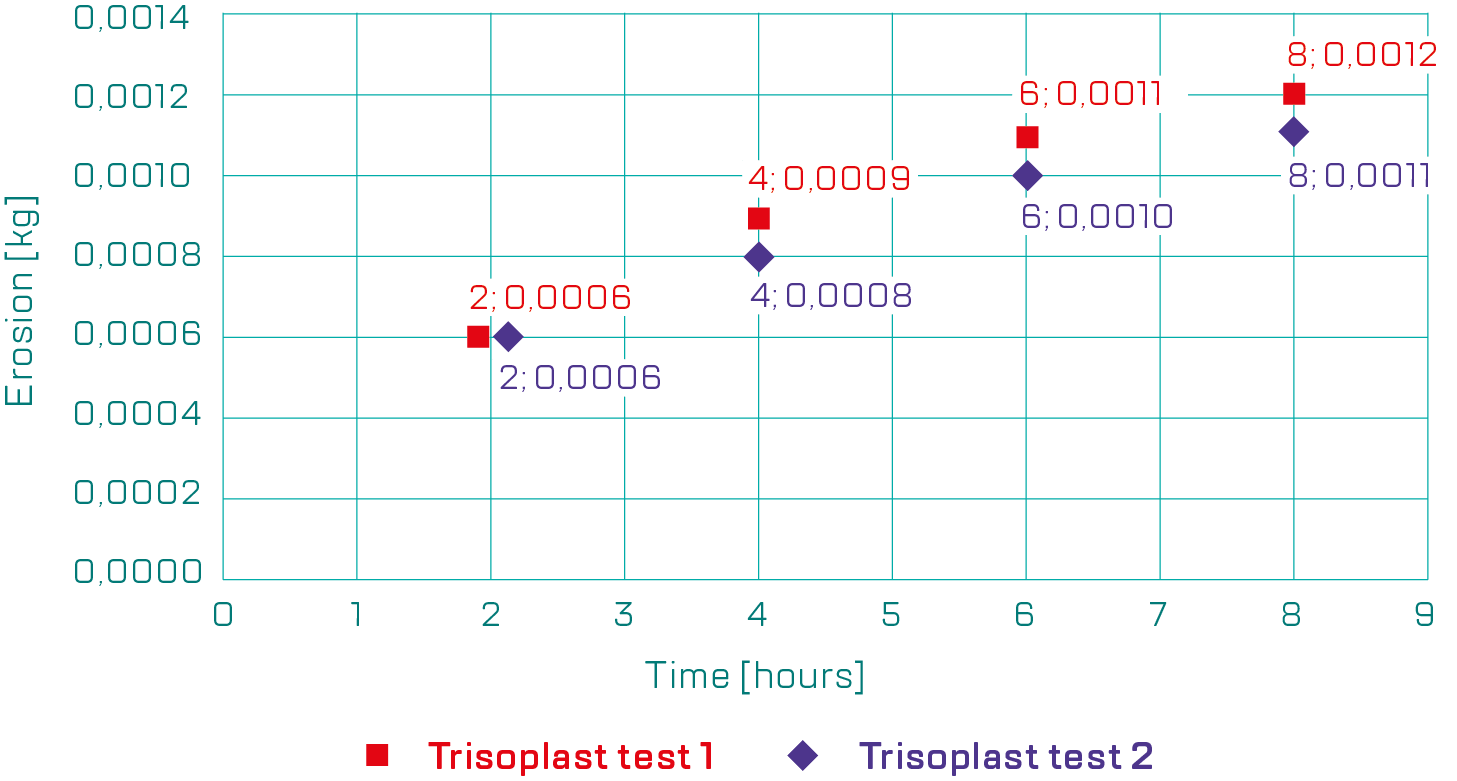

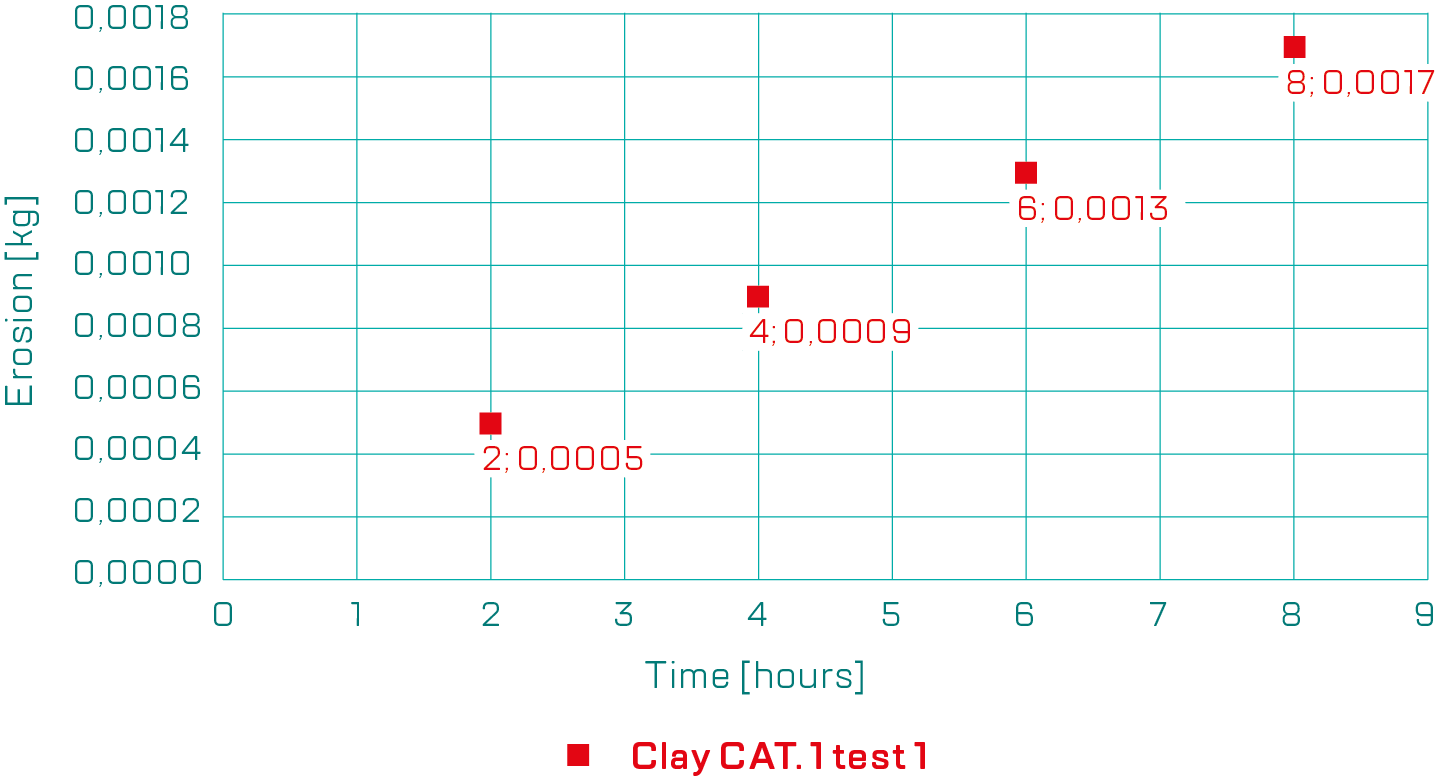

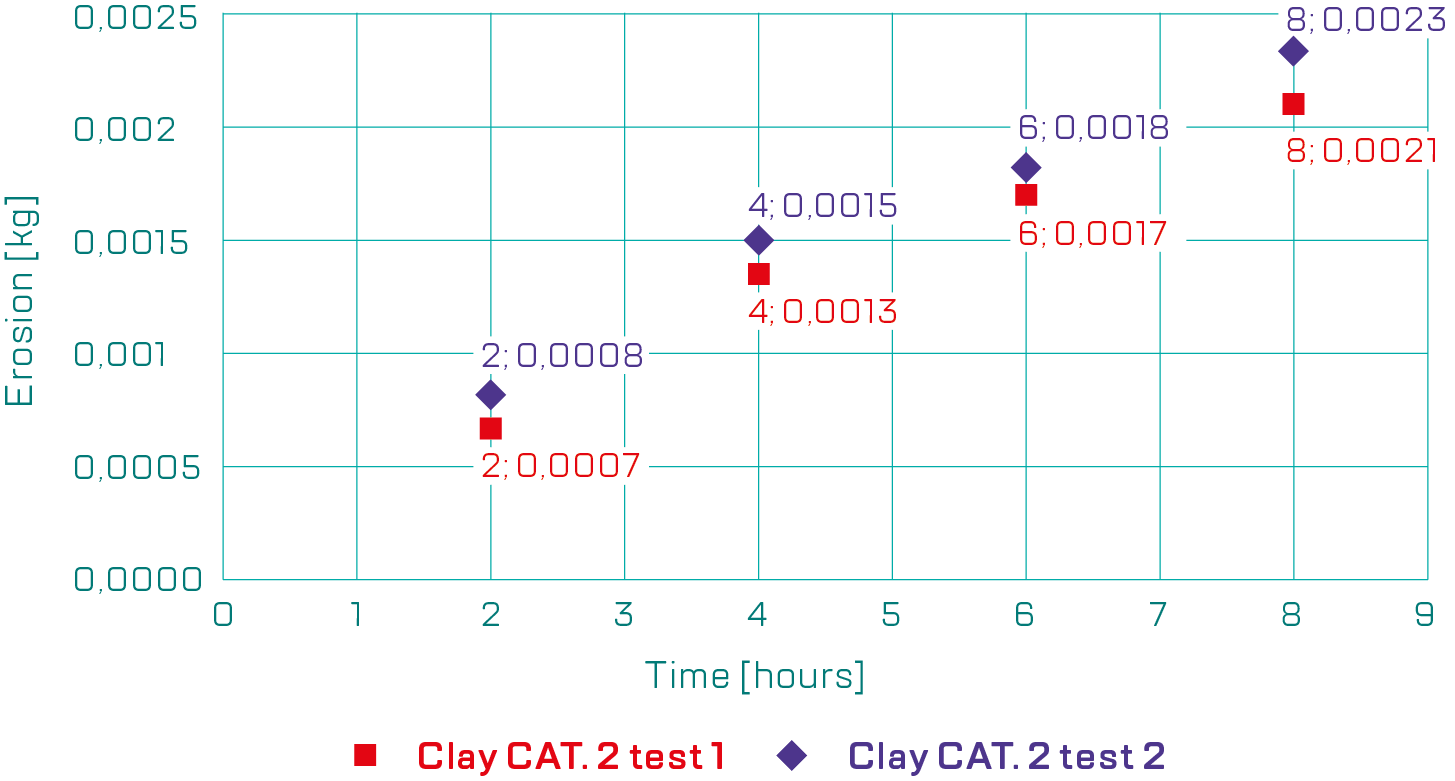

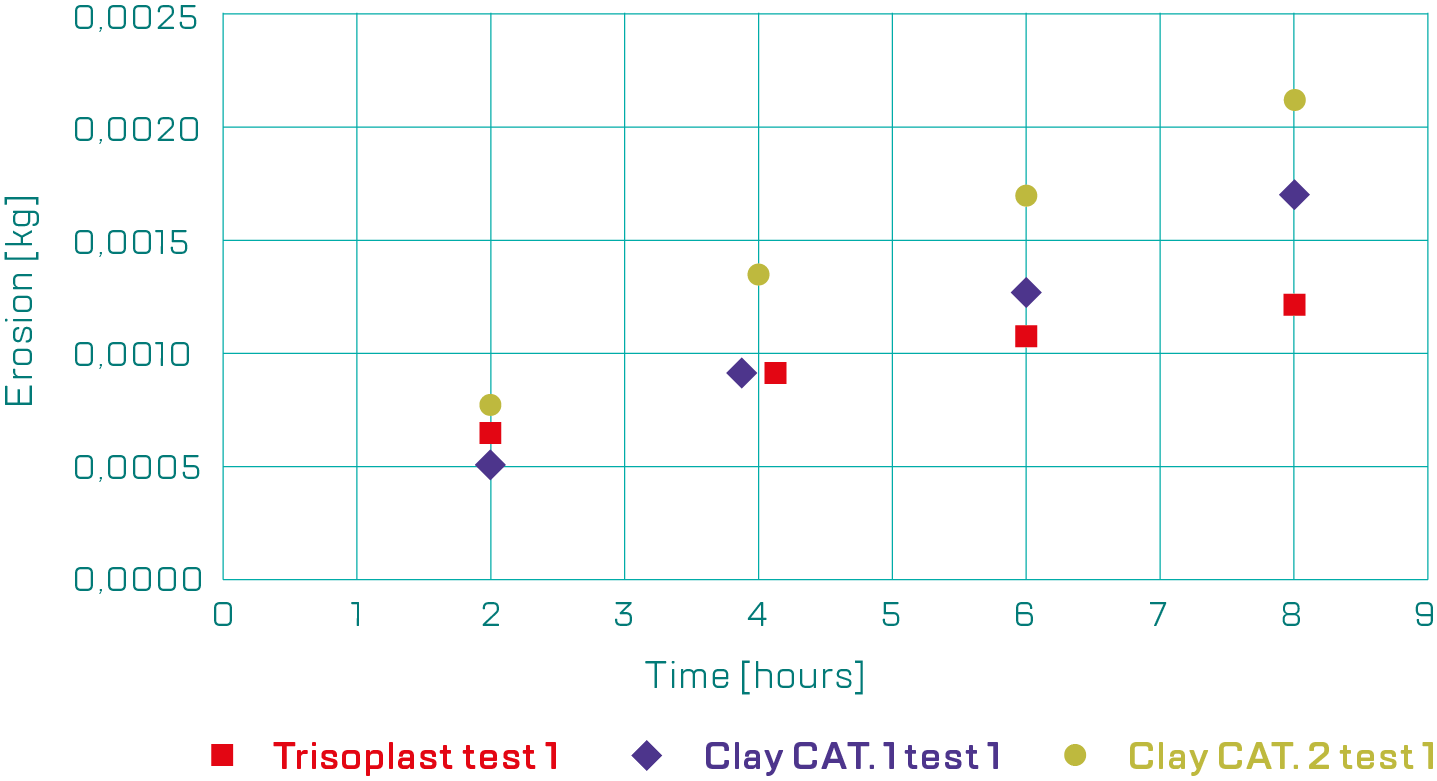

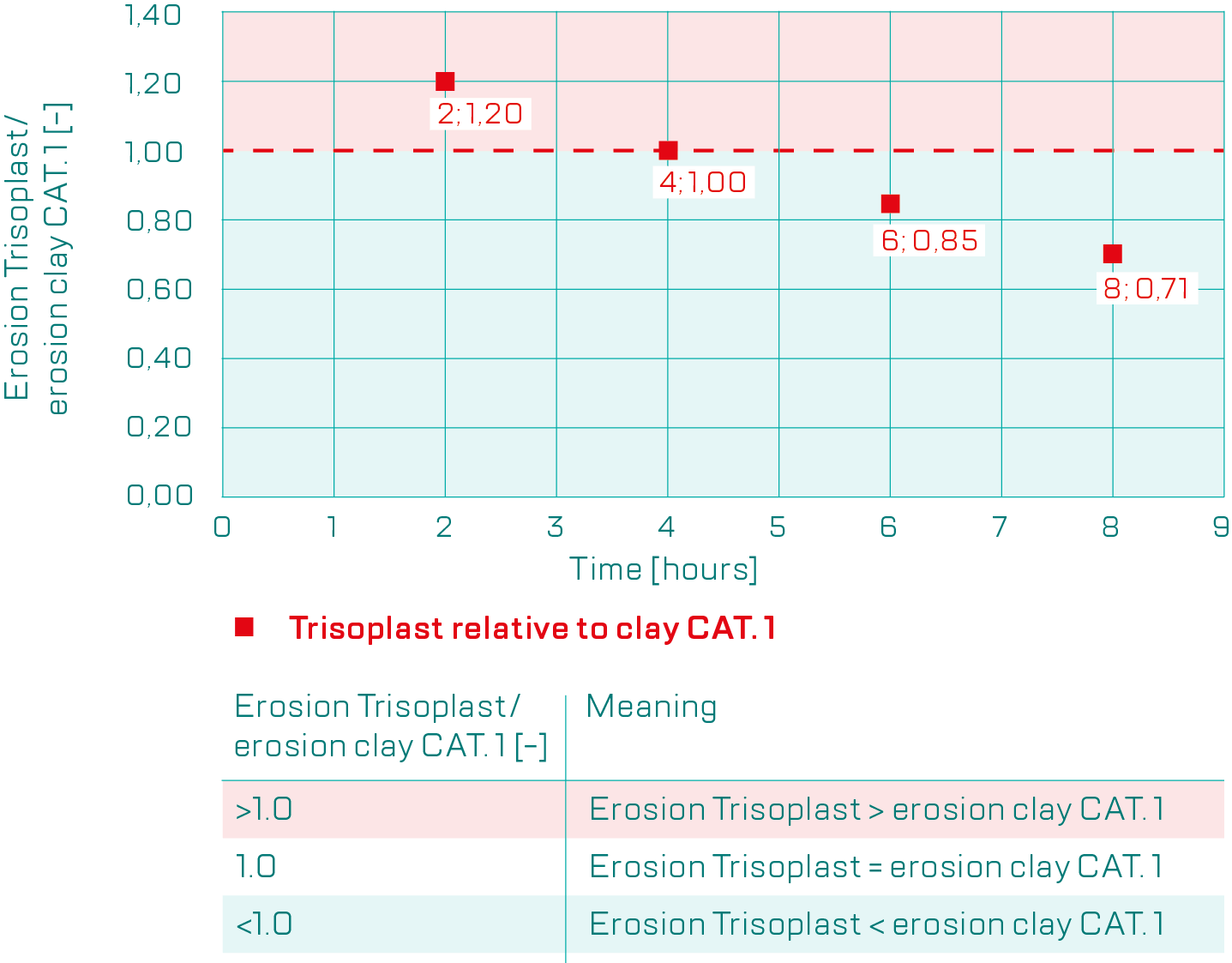

The clay layer in dykes ensures that the structure will not collapse due to erosion or instability. To test whether Trisoplast is erosion-resistant, various tests were conducted. These tests were carried out in two different flow flumes available at the Aqualab of Rotterdam University of Applied Sciences in the Netherlands.