IADC is proud to announce fourteen submissions in the running to receive the Safety Award 2024. IADC will announce submissions every week, starting from 19 August 2024. The winner will be announced on 16 October 2024.

14th nomination: DEME – Roller tracks to pass through watertight doors

DEME’s roller tracks to pass through watertight doors.

Project description

In the recent construction of vessels, a common challenge has been the installation of watertight sliding doors with high thresholds, particularly prevalent in older vessels. This obstacle significantly hampers the smooth passage of heavy loads, such as cylinder heads and pallets carrying goods. Historically, various methods were employed to navigate this issue, including the use of chain blocks, pallets with plywood and crane tracks. However, these solutions were not without risks, necessitating careful consideration of safety measures.

Recognising the need for a more efficient and safer solution, vessels have introduced roller tracks to facilitate the movement of goods through watertight sliding doors. This innovative approach has shown promising initial results, offering several advantages over traditional methods. The roller tracks not only enhance efficiency by streamlining the passage of heavy loads but also contribute to improved safety onboard.

The introduction of roller tracks marks a significant step forward in addressing the challenges associated with watertight sliding doors on vessels. This innovation not only improves operational efficiency but also mitigates risks associated with manual handling and transport of heavy goods. Moreover, the concept holds potential for further refinement and optimisation through onboard experience and feedback from crew members. Collaboration among stakeholders will play a crucial role in driving ongoing improvements and ensuring the seamless integration of this innovative solution into vessel operations.

In conclusion, the adoption of roller tracks represents a noteworthy advancement in enhancing passage efficiency and safety on vessels, ultimately contributing to improved operational performance and crew safety.

13th nomination: Cspect – ROV

Cspect’s use of mini and micro ROVs as an alternative to divers.

Project description

Cspect is an engineering company based in the Port of Ostend using remote inspection techniques to inspect assets, therefore eliminating the use of divers for inspections below water.

Mini and micro ROVs (Remotely Operated Vehicle), which are portable and versatile are used to perform underwater inspections. Due to its low weight and small size, the demob and mob costs are very low. Additionally, all Cspect’s ROVs are electrically driven without any oil on board. If green power is available, it makes it almost carbon neutral in its use and without any risk to the environment. In addition, a various number of sensors can be added onto the ROVs.

Every year, 2 to 4 fatalities occur per 10,000 divers. Some of these events were associated with divers becoming entangled in nets or divers becoming trapped underwater when they were near inflow pipes, or openings with lower pressures and were unable to free themselves from the suction pressure.

Weighing less than 25 kg, Cspect’s ROVs can be easily transported and require a team of only two engineers to operate the system. In addition, their ROVs have been optimised to sustain quite some currents. A diver can work up to 0.5 knots and is limited in working time below water whereas Cspect micro ROVs can easily work up to 2 knots with almost no limits in working time below water.

In addition to visual inspections by means of high-end cameras, the ROVs can perform other tasks, such as dimension checks, thickness measurements, sonar inspections, local cleaning and PH measurements for example. So much more than visual inspections only!

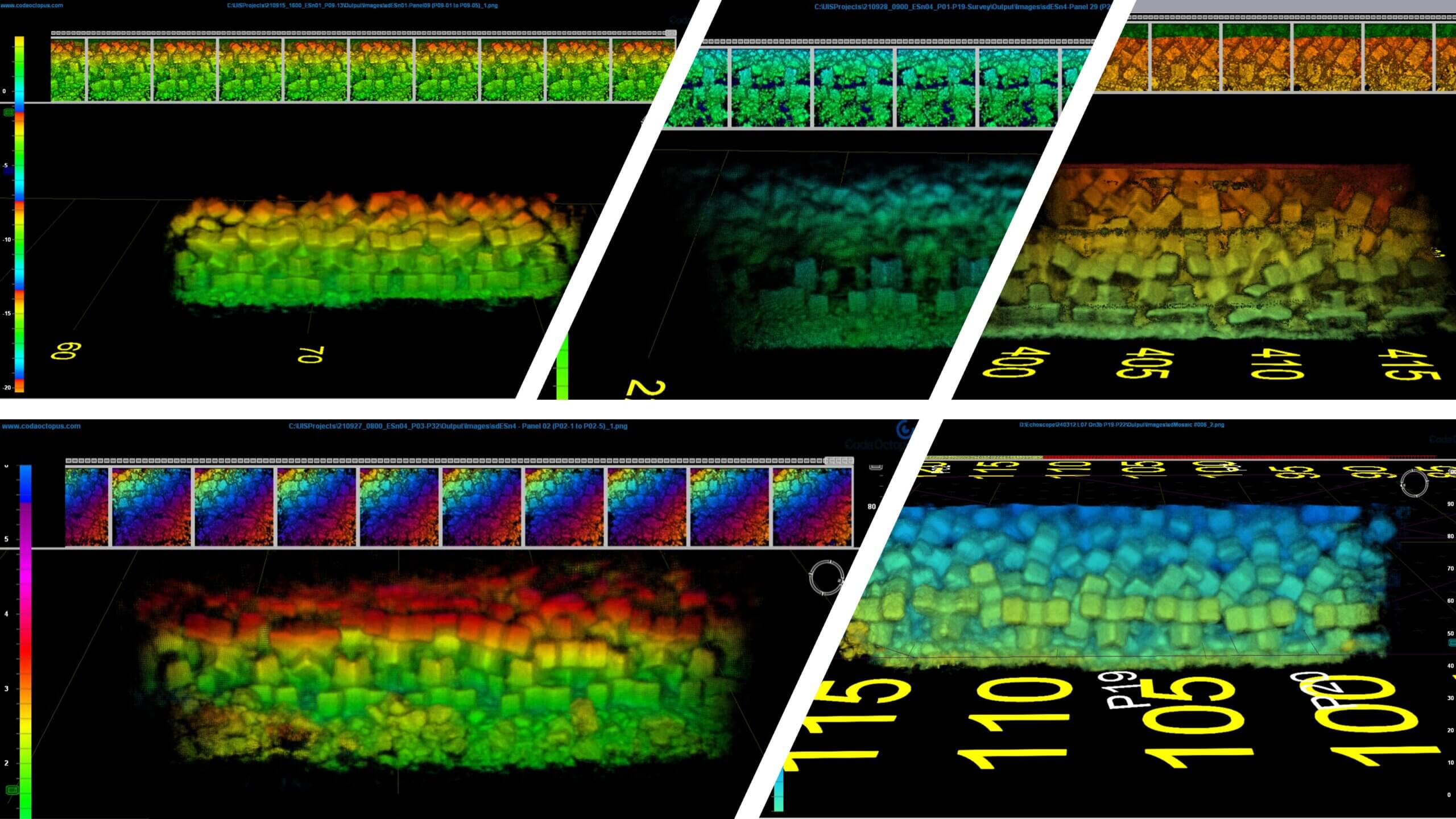

12th nomination: Van Oord – Xblocs

Van Oord’s diver less placing of concrete armour units using a real-time 3D imaging sonar (Echoscope4G®).

Project description

The diver less placement of concrete armour units (Xblocs®) utilises advance sensing technology allowing all data to be stored in an in house developed “as laid” 3D real-time block tracking structure, which includes location and orientation (roll, pitch, yaw). This data, together with high quality Echoscope4G® (real-time 3D imaging sonar developed by Coda Octopus Group Inc.) mosaics is then sent to the license holder (DMC) for immediate approval.

Due to constantly optimising the setup and workflow of placement with respect to software and hardware, this resulted in the first “diver less” block placing project. Thanks to Van Oord’s development, a team of divers assisting with the submerged placement of Xblocs® is no longer required, which in turn eliminates the risks of accidents.

The combination of advanced sensing technology with real-time tracking, which results in a 3D model, makes for a fast approval and an error free administration when utilising this system. Furthermore, the license holder's approval (DMC) of the placement by using this system is already an innovation itself.

Besides the created diver less environment, the complete process can be visualised and documented meeting the license holder’s criteria with respect to production and placement, which is a must for warranty and insurance purposes. The common denominator for Xbloc placement is an inhouse developed tool called TITAN, to create traceability in installation of objects. Every block has a unique ID to which additional information is attached and stored in a large database. A general labourer equipped with a tablet enters the Xbloc ID in the TITAN application and when it is placed by the excavator, the placement ID is automatically extracted and linked to the Xbloc ID via a web request.

Since the submerged placement without divers has been tackled, the safety potential of the "dry" blocks placement should be increased to avoid labourers standing or moving near the excavator's reach. This would ideally result in block tracking and dynamic placing for the dry blocks as well, which would rule out human assistance/involvement as much as possible.

11th nomination: Rohde Nielsen – Drag head design change

New drag head design by Rohde Nielsen.

Project description

When backfilling, the grating on the drag head very often gets blocked by rocks. To remove the rocks takes a lot of manual work and involves working in an awkward posture. A process that could easily take an hour or more and involves working under the drag head with the risk of getting hit by falling rocks.

Rohde Nielsen therefore set about changing the design of the drag head. With a movable grating, now all that has to be done is to remove a few bolts, after which the side plates and grating can be eased off, allowing the rocks to freely flow when backfilling. It eliminates both the issue causing the hazard and the need for manual handling and the dangers of working under the drag head.

The innovative design is in its simplicity. By simply changing the design from a fixed grating to a moveable one, a solution was found that greatly improves the safety of personnel. The new design has been tested for approximately 6 months with excellent results. Following the design change, Rohde Nielsen has suffered no incidents or near misses, and the plan is to start implementing the change on all its remaining vessels with a drag head on board.

10th nomination: Jan De Nul – CTV safety railing

Jan De Nul’s safety rail reduces the unsafe feeling of walking along the side to the front of the vessel.

Project description

Jan De Nul has equipped its CTV (DN97) with an accompanying safety railing, both port and starboard, that runs along to the front of the vessel, aiding people during a transfer.

For various reasons, people come aboard Jan De Nul’s Trailer Suction Hopper Dredgers on a regular basis. In general, they are trained people working within the industry but often there are people experiencing a sea transfer for the first time. Transfers at sea are a risky activity for many reasons. The unpredictability of the weather and the sea can cause accidents to occur, sometimes with fatal consequences. The safety railing ensures that a person can go to the front of the vessel from a safe place on the deck, guided by a lifeline. Only when the deckhand agrees to release you can the lifeline be disconnected from your lifejacket.

The innovative railing includes sleek design for easy (dis)assembly, adaptability to different sizes, heights and lengths, and a sturdy construction that can absorb the weight of any fall. All of which reduces the unsafe feeling of walking along the side to the front of the vessel.

The safety railing encompasses sliding metal blocks on a track into which a person clips their lifeline, which then slides along the rail as they move. This means the lifeline does not have to be loosened at any point. Just think of how you detach and reattach yourself when climbing a scaffolding. You can move from the back to the front of the vessel and vice versa in one smooth and safe movement. 10 people can use this system one after the other without the deckhand having to return the track systems.

The safety railing has been designed with usability and efficiency in mind, making it easy for crew members and employees to use. It allows the technical department to quickly understand how to assemble and dismantle it, and the simple design minimises the need for complex instructions or extensive deckhand training.

9th nomination: NMDC Group – Leading with safety programme

NMDC Group’s "Leading with Safety" programme introduces several innovative aspects aimed at revolutionising the approach to workplace safety.

Project description

The Leading with Safety programme by NMDC Group delves into the crucial intersection between leadership and workplace safety. The company emphasises that effective safety leadership goes beyond mere compliance with regulations; it requires a proactive approach that prioritises the well-being of employees.

The programme outlines strategies for cultivating a safety culture within organisations, emphasising the role of safety leadership in shaping attitudes and behaviours towards safety. NMDC Group advocates for leaders to engage with employees at all levels, encouraging open communication and active participation in safety initiatives.

Through case studies and practical workshops, the programme highlights the benefits of integrating safety into the core values and operations of an organisation. Key themes include fostering trust, promoting accountability and empowering employees to take ownership of safety. NMDC Group's insights underscore the importance of leadership commitment and consistent reinforcement of safety principles to achieve sustained improvements in workplace safety. The Leading with Safety programme serves as a valuable guide for leaders seeking to create safer, healthier and more productive work environments.

The programme aims to significantly enhance safety within the organisation by instilling a comprehensive safety culture from top management to frontline employees. Through this programme, NMDC Group fosters a proactive approach to safety, emphasising that it's not just a set of rules but a mindset and set of behaviours ingrained in every aspect of operations. Leaders within NMDC Group are equipped with the tools and knowledge to effectively communicate safety expectations, inspire trust and promote accountability throughout the organisation.

By actively involving employees at all levels, the programme encourages a sense of ownership and responsibility for safety. This inclusive approach empowers employees to identify hazards, report near misses and suggest improvements, creating a feedback loop that continuously enhances safety protocols. Furthermore, the programme emphasises ongoing training and education to ensure that everyone is equipped with the necessary skills to work safely.

Through consistent reinforcement of safety principles and celebration of achievements, the Leading with Safety programme creates a positive safety culture where safety is not just a priority but a core value. As a result, NMDC Group experiences reduced incidents, increased productivity and a safer, healthier work environment for all employees.

8th nomination: Rhosonics Analytical BV – Non-nuclear density meter SDM ECO

Rhosonics’ SDM ECO non-nuclear density meter eliminates the risk of radiation exposure for workers on and around dredging equipment.

Project description

The Rhosonics SDM ECO is a cutting-edge, ultrasonic-based instrument designed to measure slurry density in real-time, offering a safe, non-nuclear alternative for the dredging industry. It represents a significant upgrade from the SDM-4 model, featuring enhanced accuracy, faster response times, a wider operating temperature range and improved sensor design. This compact, innovative tool ensures precise monitoring of solids in liquid mixtures, making it invaluable for applications in dredging, mineral processing, construction and tunnelling.

Accurate density measurements are crucial for safety in the dredging industry as they help prevent pipeline blockages, reduce wear and tear on equipment, and ensure the stability of dredged materials. By providing real-time data, the SDM ECO allows operators to make informed decisions quickly, reducing the risk of accidents and improving overall operational efficiency. Furthermore, its non-nuclear technology eliminates the health and environmental risks associated with traditional nuclear-based density meters, aligning with modern sustainability goals.

A true revolution for safety in dredging, the Rhosonics SDM ECO, unlike traditional nuclear density meters, eliminates the risk of radiation exposure for workers on and around dredging equipment. This ensures worker safety without the need for complex radiation safety protocols, freeing up valuable time and resources. Imagine – no more need for licensing, radiation leakage tests, or the constant presence of a Radiation Safety Officer (RSO) on-site. The SDM ECO simplifies operations significantly.

But the safety benefits extend far beyond the removal of radioactive materials. The SDM ECO provides accurate real-time data on slurry density, allowing operators to catch potential problems before they snowball into serious accidents. This proactive approach helps prevent pipeline blockages, equipment wear and tear, and ensures the stability of dredged materials – all of which can lead to safety hazards on a dredging operation.

The beauty of the instrument lies in its remarkable ease of implementation. Unlike traditional nuclear gauges that require a whole list of prerequisites, the SDM ECO boasts a "plug-and-play" approach that minimises pre-installation hassles. Plus there’s no need for approvals, permits, or dedicated storage for radioactive materials.

The installation is also easy and intuitive. Its diverse fittings allow for a quick and straightforward setup. In most cases you just slide the sensor into the fitting and secure the mounting flange. Done! Additionally, the SDM ECO streamlines the calibration process without sacrificing accuracy, allowing you to get up and running quickly without wasting valuable time and resources.

7th nomination: DEME - AI camera detection system

DEME’s new AI system offers 360-degree coverage, improving safety for personnel working around operational machinery.

Project description

DEME’s improved AI Camera Detection System addresses the implementation of a new and enhanced safety system for earth-moving equipment operators. This new system, which utilises artificial intelligence and advanced cameras, is set to replace the existing r radar-based detection system currently used on wheel loaders and dump trucks.

The primary motivation for this upgrade is to address the limitations of the current system. Although it was the best available option at the time of installation, it has several drawbacks, such as a limited detection range of only 7 metres behind the machines, difficulties in detecting persons due to varying light conditions (sun and shade), and an inability to detect objects at the sides or front of the machines. The new AI camera system overcomes these limitations by providing a full 360-degree detection coverage around the equipment, enhancing overall safety.

The main goal of the new system is to improve personnel safety by preventing them from coming too close to operational machines. This is part of a broader traffic management plan that includes separated walkways as well as designated maintenance and parking areas.

Key features of the new system include object detection using radar at the rear, personnel detection with AI cameras at the front, sides and rear, and high-definition screens that display images from multiple cameras simultaneously. The system also includes visual and auditory alarms to alert operators of nearby personnel or obstacles, and the settings are locked to prevent operators from making unauthorised changes.

Test results of the new system have been positive. It effectively detects individuals, highlighting them with a red box on the screen, and the audible alarm is loud and non-adjustable, ensuring that alerts are always heard. The system provides excellent visibility in both daylight and darkness, thanks to its large 10-inch screen and the power button is deactivated to prevent accidental shutdowns.

Overall, the new AI camera detection system significantly enhances the safety of personnel working around heavy machinery by providing comprehensive detection and overcoming the shortcomings of the previous system.

6th nomination: Boskalis - Push-pipe safety clamp

Boskalis improves safety during sandfill with push-pipe safety clamp.

Project description

While a TSHD was discharging fine material, the sandfill team installed a spreader to retain the material. It was hard to notice that the material had become coarser, which caused the spreader to get blocked. This resulted in increased pressure in the push-pipes causing the last push-pipe to dislodge and material being discharged on a nearby excavator.

The excavator sustained damage due to rocks in the material and could have seriously harmed personnel in the affected area. To eliminate the hazard of dislodging push-pipes near the discharge area, a safety clamp was installed. Normally, a safety clamp is used in corners of pipes where the pressure can be higher due to the bend in the pipe.

A piece of sheet metal (25 mm thick) is sufficient to cut the safety clamp from. After cutting the metal into shape, it can be installed directly. A plug and play solution. It doesn't get easier than this. It does not require any engineering, high cost or long production times and has no negative impact on the environment.

No preparations are therefore necessary, apart from having a cutting set and sheet metal available. An easy and low-cost solution, this device can prevent incidents from happening on all sandfills throughout the entire dredging industry. After the push-pipe safety clamp was installed, no incidents occurred and the safety of personnel and equipment was ensured.

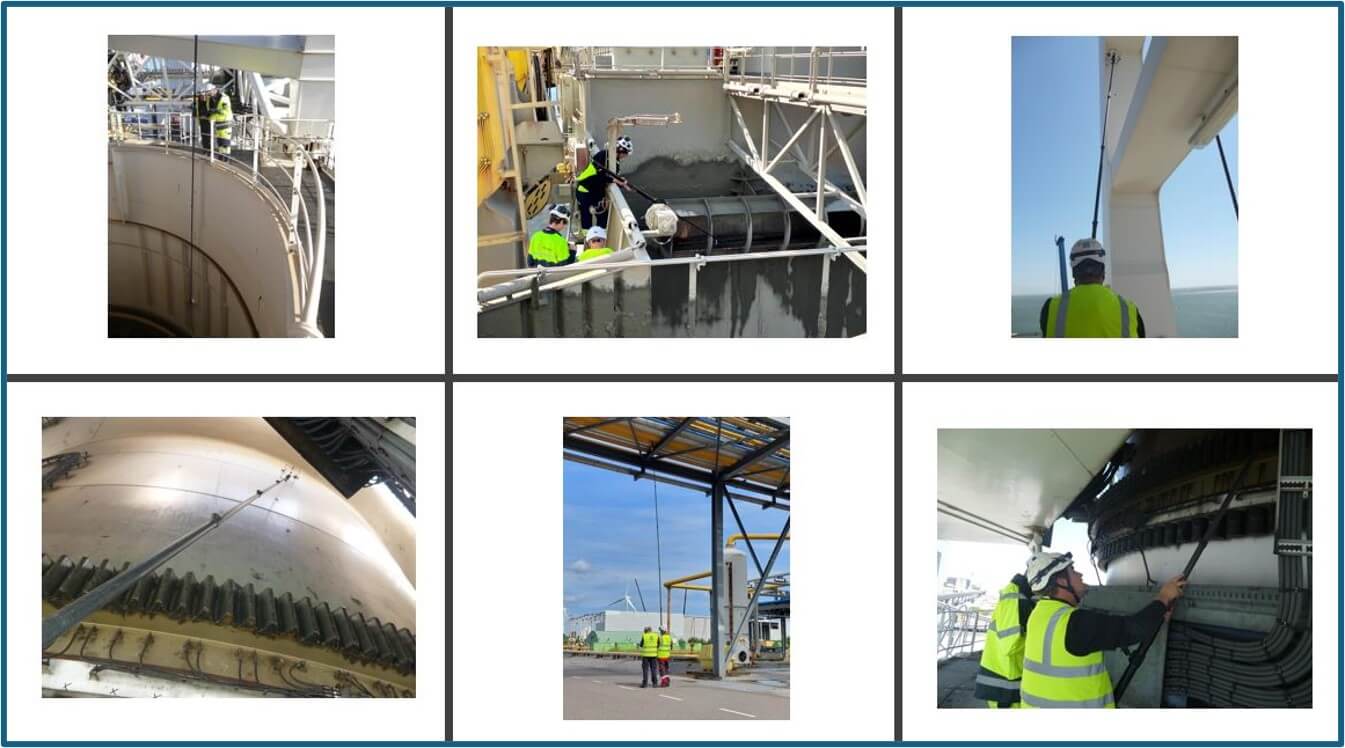

5th nomination: Cspect - ALTUM telescopic poles

Cspect’s ALTUM telescopic pole system.

Project description

The ALTUM telescopic pole system has been developed to easily perform inspections and actions at height or depth. The system, which is patented, is an “in-house” development by Cspect.

It consists of different modules that can be attached on top of an “ultra-light” telescopic pole of maximum 22 metres. Weighing less than 5 kg, the system is easily transportable and can be carried as standard luggage/baggage on a plane.

It is a safe, reliable and cost-effective solution to execute general and detailed inspections.

The system avoids the need to use scaffolds, ladders, rope access, cherry pickers or cranes for visual inspection at height or depth and thickness gauging of structures at height. For example, it can be used to check the hopper walls without entry, check the overboard depth marks without deploying rescue boats, check the overflows without entry, check pipelines at height, check the inside of tanks without entry, check the welding seams of crane structures or have a quick check of any structure at height, the list goes on.

With an easy setup, the ALTUM telescopic pole can be deployed for multiple hours without battery stress. Moreover, the system has the additional advantage that is it not bound by any rule or regulation as is the case with the use of drones for example.

Two modules are currently available. The ALTUM with VISUAL module for performing close-up inspections allows 360 gimbal of a stabilised controlled camera with a 62MP output up to 20 metres high or deep. The ALTUM with the UTM module allows Ultrasonic Thickness Measurements to be performed with grinding and hammering facility of steel structures up to 18 metres high.

In terms of training, just 2 hours in necessary to learn how to operate the ALTUM with the visual module and 1 day to operate the ALTUM with the UTM module.

4th nomination: DEME - Access to void spaces

DEME’s access to void spaces – safety improvement design.

Project description

To enhance safety and efficiency in accessing and rescuing from confined spaces with vertical entry, DEME has developed a new safety device that is designed to be easily implemented in areas with limited space and uneven surface.

Void spaces include discharge channels of bow coupling, jet water lines to the hopper, power cables to thrusters, general hydraulic lines and fuel lines. The necessity arose from the installation of new electrical cables for an e-excavator, requiring access approximately every six weeks. The goal is to enhance safety by providing a stable and secure method for workers to enter and exit these hazardous void spaces efficiently.

Current configurations involve using long, uninterrupted ladders over 8 meters, which pose safety risks due to limited space as well as obstructions that hinder safe passage and setup of tripods.

Constructed from lightweight aluminium for ergonomic handling, the new design features versatile mounting with adjustable slot holes to ensure that the device fits securely over any manhole of the corresponding size. The design is exceptionally user-friendly in every aspect. There are no movable parts or components to be mounted, except for the fall arrestor and/or retrieval system.

In addition, improved accessibility is provided by an integrated handgrip, which aids in safely entering and exiting a confined space. The capabilities of a tripod are incorporated into the device with regards to emergency rescue. It reduces structural impediments, guaranteeing safe passage and a clear evacuation area. Essentially, establishing an open space environment around the manhole unlike a traditional tripod.

The minimalistic design is easy to secure, ensuring it remains stable under any conditions, yet it can still be easily relocated when needed. Designed and built in compliance with EN795 and EN1090 standards, the device can be fitted with a hinged grating without a locking mechanism. With this additional element, a ventilator can be installed on top to provide forced ventilation. It also ensures that individuals cannot inadvertently step into an open manhole. It can also be painted in a high-visibility colour (black/yellow) to indicate a confined space working area with its potential hazards.

3th nomination: Van Oord - ROV inspection quay walls

Van Oord’s use of ROVs for underwater inspections eliminates the need for human divers in quay wall inspections.

Project description

On infrastructure projects, there are a lot of underwater inspections in building pits and close to quay walls, which are usually executed by human divers. This way of working is not without risks and unfortunately, Van Oord has had fatal accidents in the last years. To avoid human diver incidents, Van Oord Survey division deployed diver less inspections by using a remote operated vehicle (ROV).

Third-party hardware (ROV) in combination with Van Oord’s inhouse developed survey software is a step forward with respect to safety, efficiency and cost reduction The combination of using the ROV with the survey software turns out to be the winning solution for quay wall inspections. The software has been used for many years in Van Oord’s dredging activities and is well proven.

The combination of viewing sonar and camera images in real time on a screen, is a great improvement instead of the hands and eyes of a human diver. With the presentation of the inspection results via Van Oord’s GIS viewer, the information can easily be shared with all the stakeholders. In addition, the easy to operate equipment makes it very flexible to deploy on projects. This new way of working with ROVs reduces the need of human divers up to 90%. By avoiding human involvement in underwater inspections, Van Oord has reduced the chance to (fatal) injuries to zero. In case a situation arises where a human diver is needed, the work area will first be secured by an ROV inspection.

2nd nomination: Jan De Nul - Cutter head staircase

Jan De Nul’s new cutter head staircase design allows technicians to maintain safe and efficient working postures, reducing associated risks of lifting and working at height.

Project description

The issue of organising safe repairs on cutter heads has persisted for a long time. Numerous attempts have been made to improve the situation, but unfortunately none of the previous initiatives have been successful. The reasons for these shortcomings have varied, including large and cumbersome structures, difficulty in installation or repositioning, in addition to continued exposure to risks related to lifting and working at height.

Jan De Nul believes its new design has a greater chance of success as it was developed by the welding team itself. With their firsthand experience and deep understanding of the practical challenges, they have crafted a solution that addresses the main risks more effectively. This team-driven approach ensures that the design is not only practical and easy to install but also significantly reduces the associated risks as well as involved costs, making it a more viable, safer and efficient option for cutter head repairs. The staircase has been thoughtfully designed to improve user comfort and reduce fatigue. Each step is positioned at an optimal height and angle, allowing technicians to maintain safe and efficient working postures. This significantly lowers the risk of musculoskeletal injuries compared to traditional platforms, ensuring that technicians can work longer without discomfort.

The modular nature of the staircase allows for easy disassembly, transport and reassembly. The design enables quick and efficient set up in various locations, making it highly adaptable to different sizes and types of cutter heads. The modular construction is particularly beneficial in small-scale workshops where space may be limited, as the staircase can be reconfigured to fit the specific needs of the environment. The staircase is versatile and can be adapted to different sizes and heights of cutter heads. Its adaptable nature makes it suitable for a wide range of environments and applications, ensuring it meets the diverse needs of various projects.

Designed with user-friendliness in mind, the staircase is easy to assemble and use. It requires minimal training for welders, which reduces downtime and increases operational efficiency. The intuitive design ensures that technicians can quickly and safely set up and utilise the staircase without the need to access the cutter head without protection against falling at height. The staircase includes non-slip steps and sturdy railings that provide additional safety for users.

The idea and creation of the metal staircase was led by an experienced welder foreman. The design team, with many years of hands-on experience between them, brought practical knowledge and expertise to the project. Their deep understanding of the working conditions in the workshop played a crucial role in shaping the design and functionality of the staircase. This staircase, which is welded to the cutter head, improves operational control by providing stable and secure access to cutter heads, reducing the risk of falls and slips compared with previous initiatives. By reducing the need for rigging and lifting operations to position fixed platforms, it lowers the exposure to hazards related to lifting operations and working at height.

1st nomination: Boskalis - Proximity Warning System, Oxagon project

Boskalis installs proximity warning system (PWAS) on moving equipment to reduce the risk of incidents between personnel and machinery.

Project description

The Proximity Warning System (PWAS) serves as a safeguarding measure designed to protect humans from the dangers posed by moving machinery, such as bulldozers and excavators.

In the context of the Oxagon project in Saudi Arabia, there were near misses of potentially hazardous encounters between personnel and machinery, which could have led to dangerous or even life-threatening situations. The challenge lies in the operators of bulldozers and excavators, who may not always be aware of the presence of a person nearby, particularly someone approaching from the sides and in their blind spots. To mitigate these risks, Boskalis installed the PWAS system that alerts operators through voice messages and visual signals on a monitor. It features adjustable warning distances tailored to different types of machinery, enhancing safety protocols.

Employing cameras and AI software capable of distinguishing a person from inanimate objects, the system is cost-effective, priced at approximately EUR 1,200 in Saudi Arabia. For the Oxagon project, Boskalis equipped 20 PWAS systems at an overall cost of EUR 24,000. The system is easy to implement on standard equipment as there are no modifications or adaptations required. The installation process, which involves four cameras and a monitor, is swift and only took 2 hours. Since installing the PWAS system, there have been no recorded incidents of dangerous interactions between humans and machinery.